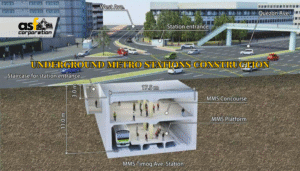

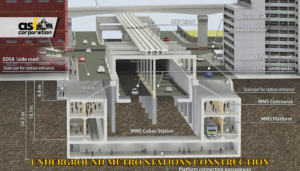

Introduction to Underground Metro Construction

With Dhaka evolving into one of South Asia’s most congested metropolises, the demand for efficient public transportation systems is critical. The expansion of underground metro construction projects—spearheaded by the Mass Rapid Transit (MRT) network—is not only a testament to urban ambition but a necessity for mobility, sustainability, and economic growth.

Importance of Metro Systems in Urban Bangladesh

Dhaka’s overcrowded roads and underdeveloped transit corridors hinder productivity and urban quality of life. Modern metro stations, especially underground metro construction ones, offer high-capacity, punctual, and climate-resilient solutions. Their ability to operate independently of existing road traffic makes them vital in areas where land is scarce and congestion is chronic.

Why Underground Stations Are Preferred in Dense Cities Like Dhaka

In Dhaka’s urban core, acquiring space for traditional surface construction is expensive and disruptive. Underground metro stations are discreet, avoid surface encroachment, and maintain the city’s architectural and historical integrity. Moreover, they are better suited to areas near key landmarks, commercial districts, and government facilities.

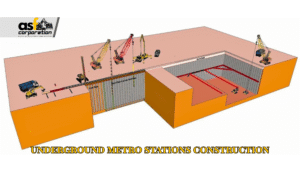

Overview of Underground Metro Construction Methods

Two primary engineering methods dominate underground metro construction:

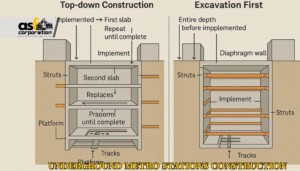

Top-Down Construction Method

Bottom-Up Construction Method

Each method suits different urban, geotechnical, and environmental conditions.

Applicability in Bangladesh’s Urban Landscape

The right underground metro construction method depends on:

Groundwater levels

Subsoil types (silt, clay, sand)

Density of utilities

Surrounding infrastructure

Surface activity levels

In Dhaka, both methods are applied contextually, depending on the site.

Top-Down Construction Method Explained

Top-down construction builds from the surface downward, allowing surface traffic to resume quickly. This technique constructs structural slabs progressively as the excavation deepens.

Ideal Urban Scenarios for Top-Down Implementation

Near busy roadways like Mirpur Road or Motijheel

Adjacent to fragile heritage buildings

Locations requiring quick surface restoration

Step-by-Step Execution of the Top-Down Method

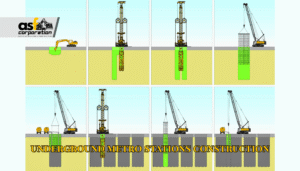

Role of Diaphragm Walls or Secant Piles

These form permanent retaining walls, holding back soil and water. Their installation precedes excavation and defines the perimeter of the metro station.

Initial Shallow Excavation

A minor dig down to the roof slab level prepares the site. This controlled excavation limits soil destabilization and minimizes disturbance.

Construction of the Roof Slab

This first structural slab is cast in situ. It becomes a platform for reinstating traffic and prevents external elements (rain, noise, dust) from affecting deeper construction stages.

Excavating Below the Roof Slab

Work proceeds through designated opening shafts, using cranes and temporary supports like struts or anchors. Specialized machinery is essential here.

Sequential Construction of Intermediate Slabs

As the dig deepens, floor slabs are built layer by layer—each helping stabilize excavation and reducing wall deflection.

Construction of Final Base Slab

The bottom-most slab provides structural closure and final support. Waterproofing, reinforcement, and drainage installations are completed here.

Interior Finishes and Installations

Once the structural shell is complete, installation of HVAC, lighting, escalators, lifts, and architectural finishes transforms it into a fully operational transit space.

Advantages of Top-Down Construction

Minimal surface disruption—essential in congested zones

Early traffic restoration

Progressive support reduces soil movement

Better suited for high groundwater environments

Challenges of Top-Down Construction

Requires complex sequencing

Needs highly skilled labor and specialized equipment

Restricts access for heavy machinery due to early slab placement

Bottom-Up Construction Method Explained

The bottom-up method excavates to the final depth before building any permanent slabs. This traditional technique is linear, starting from the base and moving upward.

Settings Where Bottom-Up Is Effective

Open construction zones like MRT depot areas

Less traffic-intensive regions

Sites with lower groundwater risks

Step-by-Step Execution of the Bottom-Up Method

Installation of Diaphragm or Retaining Walls

Retaining structures are first built to resist lateral soil and water pressure during excavation.

Excavation to Final Station Depth

Soil is completely removed, sometimes over 20 meters deep, with bracing systems installed at various stages to prevent wall collapse.

Pouring the Base Slab

The station floor is constructed first, acting as a waterproof platform and base for utilities and drainage systems.

Construction of Intermediate and Roof Slabs

Slabs and walls are constructed in ascending order. Pillars and walls rise along with each slab until the roof is cast.

Final Works and Station Commissioning

Mechanical, electrical, and architectural works follow. The open excavation simplifies logistics and project supervision.

Advantages of Bottom-Up Construction

Simpler sequencing

Full site access for large machinery

Easier quality assurance and inspections

Challenges of Bottom-Up Construction

Greater surface disruption affects traffic and commerce

Requires extensive temporary bracing

Not ideal for high groundwater areas

Vulnerable during monsoon seasons

Comparative Analysis: Top-Down vs Bottom-Up

| Feature | Top-Down | Bottom-Up |

|---|---|---|

| Surface Disruption | Minimal | High |

| Access for Equipment | Limited | Full |

| Construction Speed | Medium (progressive) | Quick Start, Slower Completion |

| Traffic Impact | Low (surface restored early) | High (excavation delays surface use) |

| Groundwater Handling | Excellent | Challenging |

| Suitability for Dhaka | High | Medium |

Groundwater Management in Dhaka

Dhaka has a shallow and aggressive water table, especially during monsoon. Top-down methods handle this better by:

Using sealed diaphragm walls

Limiting open exposure of soil

Reducing dewatering costs

Soil Stratification and Engineering

The city’s soil layers vary from soft silts to dense sands, requiring adaptive designs. Top-down construction supports sequential slab installation which distributes earth pressure gradually.

Monsoon Challenges

Bangladesh’s seasonal flooding severely affects excavation-based projects. Top-down sites are covered early, while bottom-up methods often require temporary sump systems.

Traffic and Public Safety

In traffic-dense areas, top-down construction ensures:

Earlier road reinstatement

Fewer lane closures

Enhanced pedestrian safety

Utility Relocation and Service Continuity

Most utility lines in Dhaka are shallow and unmapped. Top-down allows phased relocation and re-routing. Bottom-up often mandates full utility shutdown and rebuilding.

Structural Safety for Surrounding Buildings

Top-down reduces ground vibration and lateral pressure—important near:

Hospitals (e.g., BSMMU)

Heritage buildings (e.g., Curzon Hall)

Schools and dense housing blocks

Cost Analysis: Short vs Long-Term

While top-down has:

Higher initial costs (due to sequencing and equipment)

It often results in:Lower compensation payouts

Faster economic restoration

Lower long-term maintenance from better soil control

Technology, Manpower & Equipment Needs

Top-down construction demands:

Specialized excavation rigs

Trained urban geotechnical engineers

Real-time monitoring tools

Bottom-up methods depend more on standard excavators and crane systems.

Case Studies for Reference

Singapore MRT: Top-down used near Orchard Road

Delhi Metro: Mixed methods based on urban density

New York Second Avenue Subway: Bottom-up used in wider avenues

Dhaka MRT Line-6: Both methods utilized based on soil reports and traffic planning

Current Practices in Dhaka MRT Projects

Motijheel & Paltan Stations: Top-down due to traffic

Depot Areas (Uttara): Bottom-up due to space availability

MRT Line 1 and 5 are also expected to use both, depending on site-specific geotechnical reports

Bangladeshi Construction Regulations

Overseen by:

RAJUK – Urban planning and zoning

PWD – Public infrastructure standards

DOE – Environmental impact clearances

Public Communication and Safety

Effective strategies include:

Noise and dust control

Clear signage and pedestrian redirection

Community engagement through local meetings

Sustainable Engineering Initiatives

Use of recycled construction material

Adopting modular construction techniques

Integration of solar-powered lighting and drainage sensors

Conclusion: Selecting the Right Method for Dhaka

Top-down construction is becoming the preferred method in high-density areas of Dhaka due to:

Reduced disruption

Better groundwater management

Safer integration with existing infrastructure

Bottom-up remains valuable in open, low-traffic zones.

The future of underground metro construction in Dhaka hinges on tailored engineering, policy support, and community alignment.

FAQs

When should the top-down method be used?

When traffic needs to flow, utilities must remain intact, or nearby structures require protection.

Which method is more cost-effective for Dhaka?

Top-down may cost more upfront but reduces externalities and long-term delays.

Can these methods handle high groundwater levels?

Top-down is more efficient in controlling groundwater through sealed wall systems.

Which method is safer for nearby buildings?

Top-down minimizes soil displacement, making it structurally safer in congested zones.

Is one method faster than the other?

Bottom-up can begin quicker, but top-down allows for earlier surface recovery, balancing overall timelines.

How are utilities managed during construction?

Top-down enables phased utility relocation with minimal service disruption.

Contact ASF Corporation Today

ASF Corporation

Vashantek, Dhaka Cantonment

Dhaka-1206, Bangladesh

📞 Phone: +88 01907-636827

📧 Email: info@asfcorporation.com