King Post Driving and Lifting

Sub-Service

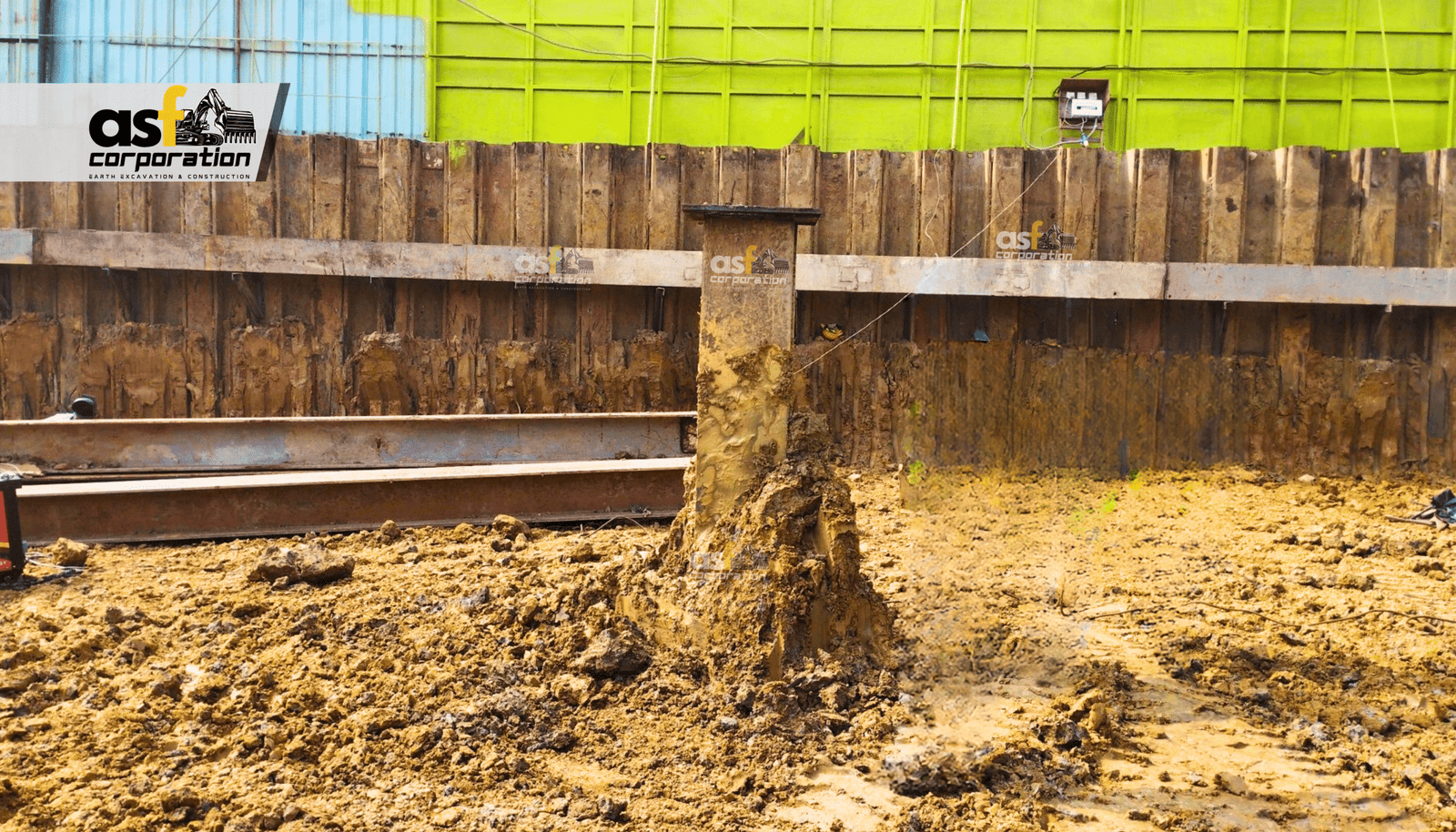

King Post Driving and Lifting: Expert Solutions for Your Construction Projects

In the dynamic world of construction and excavation, having reliable retaining wall systems is crucial for project success. King Post Driving and Lifting represents one of the most versatile and effective solutions for temporary retaining walls, providing exceptional stability and support for various construction applications. At ASF Corporation, we specialize in delivering comprehensive King Post Driving and Lifting services that ensure your projects proceed safely, efficiently, and on schedule.

Safety First

Prioritizing protection and well-being to prevent accidents and ensure security.

Competitive Pricing

Offering attractive rates to stay attractive in the market and attract customers

Timely Completion

Finishing tasks on schedule, meeting deadlines, and ensuring efficient progress.

What is King Post Driving and Lifting?

King Post Driving and Lifting is a specialized construction service involving the installation and manipulation of steel I-beam posts (king posts) to create robust retaining wall systems. This engineered system consists of steel I-beam posts connected with high-strength steel shoring panels or steel plates driven into the ground to create a reliable retaining structure.

The King Post Driving and Lifting system’s primary components include:

- Steel I-beam posts – Providing the structural framework

- High-strength steel panels – Creating the retaining surface

- Connection mechanisms – Ensuring system integrity and stability

King Post Driving and Lifting has become increasingly popular in Bangladesh’s construction industry due to its adaptability, strength, and ease of installation. As a leading construction service provider since 2017, ASF Corporation has perfected the art of King Post Driving and Lifting to deliver superior results for projects of all sizes.

Advantages of King Post Driving and Lifting

Versatility and Adaptability

King Post Driving and Lifting offers remarkable versatility across numerous construction scenarios. The system comes in various sizes of beams and panels, allowing customization to suit specific project requirements. This adaptability makes King Post Driving and Lifting an excellent choice for:

- Embankment and slope retention

- Flood defense walls

- Single-sided retaining walls

- Basement excavations where sheet piles aren’t feasible

- Loading and storage bays for loose aggregates

- Waste and recycling facilities

Cost-Effectiveness

For many construction sites, King Post Driving and Lifting represents a highly cost-effective solution, particularly in areas where sheet piles might be unsuitable due to ground conditions or very hard ground. The system provides excellent value without compromising on strength or safety.

Quick and Easy Installation

One of the most significant advantages of the King Post Driving and Lifting system is its straightforward installation process. The process is:

- Quick and adaptable

- Vibration-free, reducing on-site accident risks

- Allows for seamless on-the-spot adjustments

- Minimizes disruptions and delays

Robust and Durable Construction

Made from high-strength steel, King Post Driving and Lifting systems offer exceptional durability and longevity. This robust construction ensures that the system can withstand significant pressure and provide reliable retention in challenging environments.

Our King Post Driving and Lifting Services

At ASF Corporation, we provide comprehensive King Post Driving and Lifting services tailored to meet the unique requirements of each project. Our services include:

Expert System Design and Planning

Our team of experienced engineers works closely with clients to design King Post Driving and Lifting systems that perfectly match project specifications. We consider factors such as:

- Soil conditions and ground stability

- Required retention depth and height

- Load-bearing requirements

- Project timeline and budget constraints

This meticulous planning ensures optimal system performance and project efficiency.

Professional Installation Services

Our skilled technicians utilize advanced equipment and proven methodologies to install King Post Driving and Lifting systems with precision and care. Our installation process includes:

- Site preparation and layout

- I-beam post positioning and driving

- Panel installation and connection

- System testing and quality assurance

We prioritize safety throughout the installation process, adhering to strict protocols to protect our team and your project.

Comprehensive Lifting Solutions

In addition to king post driving, our King Post Driving and Lifting services include specialized lifting operations to support your construction needs. Our lifting capabilities include:

- Sheet pile lifting

- Heavy equipment positioning

- Material handling and placement

- Structural component lifting

Our purpose-built equipment and experienced operators ensure safe and efficient lifting operations for projects of all sizes.

Ongoing Support and Maintenance

We provide continuous support throughout your project, offering:

- Regular system inspections

- Maintenance services as needed

- Technical guidance and troubleshooting

- System adjustments to accommodate changing project conditions

Why Choose ASF Corporation for King Post Driving and Lifting?

Industry Experience and Expertise

Since our founding in 2017, ASF Corporation has grown from a trading company to a powerhouse in Bangladesh’s construction industry. Our journey has equipped us with extensive knowledge and expertise in excavation, retention, and construction solutions, including specialized King Post Driving and Lifting systems.

Comprehensive Equipment Fleet

We maintain a modern fleet of specialized equipment for King Post Driving and Lifting operations, including:

- Advanced pile drivers

- Heavy-duty cranes and lifts

- Precision excavation equipment

- Specialized installation tools

This extensive equipment inventory allows us to handle projects of any scale with efficiency and precision.

Highly Skilled Team

Our operations are powered by a team of highly skilled engineers and technicians who ensure precision and professionalism at every phase of construction. Each team member undergoes rigorous training and certification to maintain our high standards of quality and safety.

Government-Approved Contractor

As a government-approved first-class contractor, ASF Corporation maintains the highest standards of quality and compliance. This certification reflects our commitment to excellence and adherence to industry regulations.

Commitment to Safety

Safety is paramount in all our operations. We implement comprehensive safety protocols and provide thorough training to all team members. Our commitment to safety is reinforced by industry certifications and a dedication to continuous improvement.

Applications of King Post Driving and Lifting

Basement Excavations

King Post Driving and Lifting excels in basement excavation projects, particularly in urban environments where space is limited and traditional sheet piling may not be feasible. The system provides reliable retention while allowing for clear working areas, facilitating efficient basement construction.

Embankment and Slope Retention

For projects requiring embankment or slope stabilization, King Post Driving and Lifting offers excellent retention capabilities. The robust construction and adaptable design make them ideal for preventing soil erosion and maintaining slope integrity.

Flood Defense Walls

King Post Driving and Lifting can be effectively deployed as temporary or semi-permanent flood defense structures. Their quick installation and strong retention properties make them valuable assets in flood-prone areas or during emergency situations.

Loading and Storage Bays

The versatility of King Post Driving and Lifting makes it an excellent solution for creating loading and storage bays, particularly those dealing with loose aggregates, waste, and recycling materials. The system’s strength and durability ensure long-term performance in these demanding applications.

Our Process

Initial Consultation and Site Assessment

Our process begins with a thorough consultation to understand your project requirements. We conduct comprehensive site assessments to evaluate ground conditions, access limitations, and potential challenges.

Custom System Design

Based on our assessment, our engineering team develops a custom King Post Driving and Lifting system design tailored to your specific needs. We consider factors such as retention requirements, soil conditions, and project timeline to create an optimal solution.

Material and Equipment Preparation

Once the design is approved, we prepare all necessary materials and equipment for installation. Our logistics team ensures that everything is ready for deployment according to your project schedule.

Professional Installation

Our experienced installation team executes the plan with precision and care. Using specialized equipment and proven techniques, we install the king post system efficiently while maintaining the highest standards of quality and safety.

Quality Assurance and Testing

After installation, we conduct thorough testing to ensure the system meets all performance requirements. Our quality assurance process includes structural integrity checks, alignment verification, and load testing as needed.

Ongoing Support

Throughout your project, we provide continuous support and monitoring to ensure the king post system performs optimally. Our team is always available to address any concerns or make necessary adjustments as your project progresses.

Recent Projects

ASF Corporation has successfully completed numerous King Post Driving and Lifting projects across Bangladesh. Our recent work includes:

- Basement Excavation Projects: We recently broke ground on a new basement excavation project, utilizing our precision equipment and skilled crew to ensure a safe and efficient process.

- Sheet Pile Solutions: Our expertise extends to comprehensive sheet pile services, including supply, rent, and full driving services for foundation protection and excavation support.

- Land Development and Infrastructure: We’ve completed various land development and infrastructure projects, incorporating king post systems for effective soil retention and site stability.

Frequently Asked Questions

What is King Post Driving and Lifting?

King Post Driving and Lifting is a specialized construction service that involves the installation of vertical steel columns (king posts) at intervals of 1-3 meters with infill panels, typically made of precast concrete, placed between them. The system creates a strong structure for soil retention while providing flexibility in design and application.

What materials are used for King Post walls?

The King Post Driving and Lifting process primarily uses galvanized steel for the posts to prevent rust and corrosion, giving them a lifespan of 45-60 years. The infill panels are typically made of reinforced precast concrete, though timber, stones, or bricks can also be used. Concrete panels are most common as they provide superior structural stability and durability.

How deep should King Posts be installed?

In King Post Driving and Lifting operations, the depth of king posts should be approximately the same as the height of the retaining wall. The post hole should have a minimum of 100mm cement cover below the steel column and typically requires a diameter of around 450mm to ensure proper stability and support.

How is King Post Driving and Lifting performed?

The King Post Driving and Lifting installation process is relatively straightforward:

- A vertical hole is bored using a piling rig or auger

- Wet concrete is poured into the hole

- The steel column is inserted and temporarily supported in a vertical position

- Once the concrete has set, the wall panels are lowered into place between posts

- The area behind the wall is filled with soil or earth

What are the advantages of King Post Driving and Lifting?

King Post Driving and Lifting offers numerous benefits including:

- Quick and easy installation as they use precast components

- Cost-effectiveness compared to concrete and sheet-piled walls

- Silent and vibration-free installation

- Ability to use recycled materials as infill

- Suitability for both temporary and permanent retention

- Environmental friendliness due to using less steel than alternatives

- Flexibility to accommodate uneven ground and varying land conditions

- Easy disassembly when needed

Can King Post walls be used for decorative purposes?

Yes, walls created through King Post Driving and Lifting can be decorative as well as functional. Instead of using single vertical slabs of reinforced concrete, modular panels with different textures, colors, and aesthetics can be used. These can mimic the appearance of timber fences or walls built with individual stones, often with very convincing results.

What are the different types of King Post systems?

While the basic King Post Driving and Lifting system consists of vertical posts with infill panels, there are variations in architectural applications:

- Standard King Post – a central vertical post supporting a beam from a truss apex

- Double King Post – featuring two vertical posts for longer spans

- Suspended King Post – where the post is suspended from rafters rather than connected to the tie beam

- King Post Truss – a triangular structure with two principal rafters and a vertical central post

What are the limitations of King Post Driving and Lifting?

Despite their advantages, King Post Driving and Lifting systems have some limitations:

- Limited lifespan compared to some permanent structures

- Style limitations for certain architectural applications

- Unsuitability for regions prone to earthquakes or high winds

- May require additional support in certain soil conditions or for higher walls

What are common applications for King Post Driving and Lifting?

King Post Driving and Lifting is used in various settings including:

- Holding back embankments on industrial sites

- Supporting large-scale infrastructure projects

- Creating stepped or terraced gardens in residential properties

- Temporary excavation support

- Permanent retention structures for basements and foundations

What sizes are typically available for King Post infill panels?

The panel sizes for King Post Driving and Lifting systems vary based on design requirements and wall height. Typical dimensions include:

- Length: 1-3 meters

- Height: 1-1.5 meters

- Thickness: 100-250mm (common options include 100mm, 150mm, 200mm, and 250mm)

These dimensions can be adjusted according to the specific design needs and load requirements of the retaining wall.

Ready to Start Your Project?

Don’t compromise on quality and safety for your construction retention needs. ASF Corporation offers industry-leading King Post Driving and Lifting services backed by years of experience and a commitment to excellence.

Contact Us Today

ASF Corporation

Vashantek, Dhaka Cantonment

Dhaka-1206, Bangladesh

Phone: +88 01907-636827

Email: info@asfcorporation.com

Our team is ready to discuss your project requirements and provide expert solutions tailored to your specific needs. Whether you’re planning a basement excavation, embankment retention, or any other construction project requiring robust retention systems, we have the expertise and equipment to ensure your success.

Download Brochure

BENEFITS

Rigorous attention to detail ensuring accurate earthwork execution.

Application of cutting-edge technology for cost-effective operations.

Comprehensive service covering all aspects of mass earthworks.

Efficient and timely completion of tasks to keep your project on schedule.

Frequently Asked Questions (FAQ’s)

What is piling and why is it used in construction?

Piling is a deep foundation technique used to transfer structural loads to deeper, more stable soil layers when the surface soil is weak or unstable.

What are the main differences between steel, wood, and concrete piles?

Steel piles are strong and durable, suitable for deep foundations; wood piles are cost-effective and used for lighter structures; concrete piles offer high load capacity and resistance to corrosion.

When should steel piling be used?

Steel piles are ideal for projects requiring high strength, deep penetration, or in corrosive environments where coated or treated piles are necessary.

Is wood piling still used in modern construction?

Yes, wood piling is still used, particularly for temporary structures, marine applications, and in areas where soil conditions are compatible and moisture helps preserve the wood.

What are the benefits of concrete piling?

Concrete piles are highly durable, resistant to corrosion and chemical attacks, and can bear heavy loads, making them suitable for large buildings and bridges.

How long do steel, wood, and concrete piles typically last?

With proper treatment and conditions:

- Steel: 50–100+ years (depending on corrosion protection)

- Wood: 30–50 years (in wet conditions)

- Concrete: 50–100+ years

Which type of piling is most cost-effective?

Wood piles are generally the most affordable for shallow foundations, while concrete and steel piles are more costly but offer higher strength and longevity for complex or heavy structures.

Can these different types of piles be used together in one project?

Yes, mixed piling systems are sometimes used when different parts of a structure have varied load or soil requirements.

What factors determine the choice of piling material?

Soil conditions, load requirements, environmental exposure, cost, and the design life of the structure all influence the choice of piling material.

Piling is a deep foundation technique used to transfer structural loads to deeper, more stable soil layers when the surface soil is weak or unstable.

Steel piles are strong and durable, suitable for deep foundations; wood piles are cost-effective and used for lighter structures; concrete piles offer high load capacity and resistance to corrosion.

Steel piles are ideal for projects requiring high strength, deep penetration, or in corrosive environments where coated or treated piles are necessary.

Yes, wood piling is still used, particularly for temporary structures, marine applications, and in areas where soil conditions are compatible and moisture helps preserve the wood.

Concrete piles are highly durable, resistant to corrosion and chemical attacks, and can bear heavy loads, making them suitable for large buildings and bridges.

With proper treatment and conditions:

- Steel: 50–100+ years (depending on corrosion protection)

- Wood: 30–50 years (in wet conditions)

- Concrete: 50–100+ years

Wood piles are generally the most affordable for shallow foundations, while concrete and steel piles are more costly but offer higher strength and longevity for complex or heavy structures.

Yes, mixed piling systems are sometimes used when different parts of a structure have varied load or soil requirements.

Soil conditions, load requirements, environmental exposure, cost, and the design life of the structure all influence the choice of piling material.