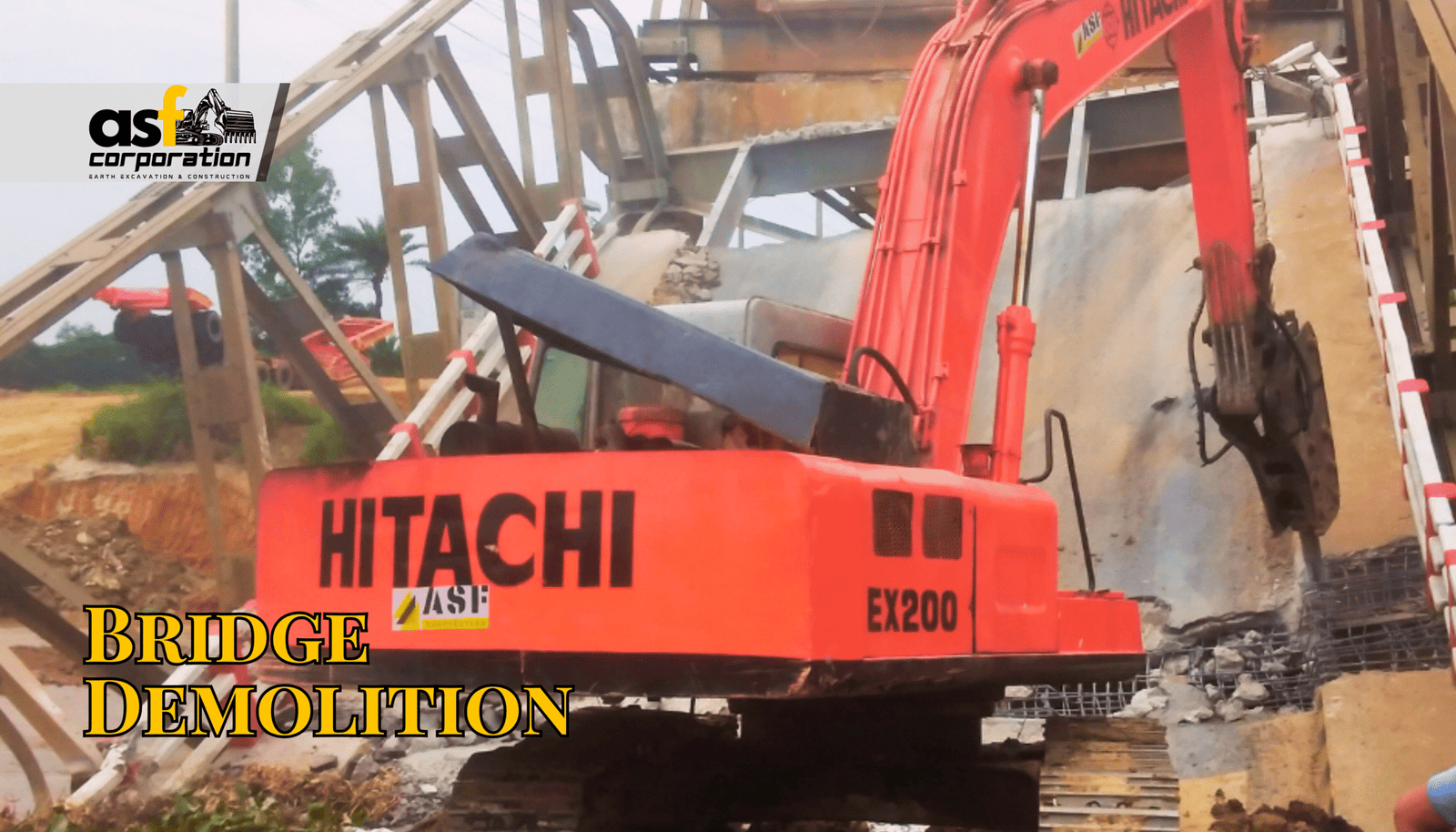

Bridge Demolition

Sub-Service

Professional Bridge Demolition Services in Bangladesh

When it comes to complex infrastructure projects, bridge demolition requires specialized expertise, advanced equipment, and meticulous planning. At ASF Corporation, we deliver comprehensive bridge demolition services throughout Bangladesh with an unwavering commitment to safety, efficiency, and environmental responsibility.

With years of industry experience and a team of highly trained professionals, we handle projects of all sizes and complexities-from small pedestrian bridges to large highway overpasses. Our expertise in various demolition techniques allows us to select the most appropriate method for each unique project, ensuring optimal results while minimizing disruption to surrounding areas.

Safety First

Lorem ipsum dolor sit amet elit tellus luctus nec ullamcorper mattis, pulvinar dapibus leo.

Competitive Pricing

Lorem ipsum dolor sit amet elit tellus luctus nec ullamcorper mattis, pulvinar dapibus leo.

Timely Completion

Lorem ipsum dolor sit amet elit tellus luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Bridge Demolition Expertise

Comprehensive Demolition Methods

At ASF Corporation, we employ a variety of specialized techniques to safely and efficiently demolish bridge structures. Our approach is always tailored to the specific requirements of each project, considering factors such as bridge type, location, environmental concerns, and project timeline.

Controlled Demolition

For larger bridge structures where traditional methods may be impractical or time-consuming, we offer controlled demolition services using precisely placed explosives. This highly specialized technique requires extensive planning and expertise to ensure the bridge collapses safely within its footprint. Our engineers conduct detailed structural analysis to identify critical load-bearing elements and design a comprehensive blast plan that prioritizes safety while minimizing impact on surrounding areas.

Mechanical Demolition

One of our most commonly employed methods is mechanical demolition, utilizing heavy machinery such as excavators, cranes, and specialized cutting tools to systematically dismantle bridge sections. This flexible approach can be adapted to various bridge designs and conditions, offering enhanced safety compared to explosive methods while allowing for efficient material recycling. Our systematic process includes thorough assessment, site preparation, and careful dismantling of steel and concrete components.

Deconstruction

For projects prioritizing sustainability, we offer deconstruction services focused on carefully dismantling structures to maximize material salvage and recycling. This environmentally conscious approach involves skilled workers systematically removing bridge components while preserving materials for reuse. The process reduces waste, provides potential cost savings through material recovery, and creates opportunities for local employment.

Specialized Equipment and Techniques

Hydraulic Breakers and Splitters

Our fleet includes advanced hydraulic breakers that can effectively break apart bridge materials, even in underwater applications for supports and abutments. We also utilize hydraulic splitting technology for precise concrete breakage with minimal environmental impact.

Concrete Sawing and Cutting

For projects requiring surgical precision, we employ specialized concrete sawing equipment to cut bridges into manageable sections that can be safely removed. This technique creates minimal noise and dust, making it ideal for environmentally sensitive areas or densely populated locations.

Robotic Demolition

Our state-of-the-art remote-controlled robotic demolition equipment allows us to access tight or hazardous areas without endangering crew members. This fumeless, low-noise approach is particularly valuable for projects in residential areas or where worker safety might otherwise be compromised.

Expandable Grout

For projects requiring non-explosive demolition, we utilize expandable grout-a non-explosive demolition agent that effectively breaks apart concrete without causing noise, vibration, or dust.

The ASF Corporation Advantage

Safety-First Approach

Safety is the cornerstone of every project we undertake at ASF Corporation. Our comprehensive safety protocols include:

- Thorough site assessment and hazard identification before work begins

- Detailed safety plans tailored to each project’s unique challenges

- Continuous structural monitoring throughout the demolition process

- Comprehensive worker training and certification

- State-of-the-art personal protective equipment for all personnel

- Strict compliance with all national and international safety standards

Our dedication to safety extends beyond our workers to encompass the public and surrounding environment. We implement robust measures including site fencing, dust and noise control, and constant structural monitoring to prevent unexpected collapses.

Environmental Responsibility

We recognize the importance of minimizing environmental impact during bridge demolition projects. Our sustainable practices include:

- Maximizing material recycling and reuse to reduce landfill waste

- Employing dust suppression systems to improve air quality

- Utilizing low-noise equipment in sensitive areas

- Implementing proper containment measures for waterway protection

- Careful handling and disposal of potentially hazardous materials

- Selecting demolition methods that minimize environmental footprint

At ASF Corporation, we believe that responsible demolition means considering the entire lifecycle of materials. We strive to recycle nearly all debris resulting from bridge demolition, significantly reducing waste in landfills.

Experienced Project Management

Our project management team brings decades of combined experience to every bridge demolition project. This expertise allows us to:

- Develop comprehensive project plans that anticipate challenges

- Adapt quickly to changing conditions or unexpected discoveries

- Coordinate seamlessly with government agencies, utilities, and other stakeholders

- Maintain strict adherence to project timelines and budgets

- Provide clear communication throughout the project lifecycle

We understand that each bridge demolition presents unique challenges. Our experienced team has the knowledge and flexibility to overcome obstacles efficiently, ensuring projects remain on schedule even in the most demanding circumstances.

Our Bridge Demolition Process

Comprehensive Assessment and Planning

Every successful bridge demolition begins with thorough assessment and meticulous planning. Our process includes:

- Detailed structural evaluation to understand the bridge’s construction and condition

- Environmental impact assessment to identify potential concerns

- Traffic and access analysis to minimize disruption

- Utility coordination to safely manage any services connected to the structure

- Development of a detailed demolition plan with contingency measures

- Obtaining all necessary permits and approvals

This critical planning phase establishes the foundation for a safe, efficient demolition process tailored to your project’s specific requirements.

Site Preparation and Safety Implementation

Before demolition begins, we carefully prepare the site and implement comprehensive safety measures:

- Installation of security fencing and appropriate signage

- Implementation of traffic management plans if required

- Disconnection and protection of utilities

- Deployment of dust and noise control systems

- Establishment of exclusion zones and safety perimeters

- Positioning of equipment and materials for optimal workflow

These preparatory steps ensure that when demolition begins, all safety systems are in place and the site is fully secured.

Systematic Demolition Execution

With planning complete and safety measures in place, our team executes the demolition according to the established plan:

- Removal of non-structural elements and hazardous materials

- Systematic dismantling following the engineered demolition sequence

- Continuous monitoring of structural stability throughout the process

- Regular safety checks and environmental compliance verification

- Efficient material sorting for recycling and disposal

Our experienced crews work with precision and care, ensuring each phase of demolition proceeds safely and according to plan.

Material Processing and Site Restoration

Following the physical demolition, we focus on responsible material handling and site restoration:

- Sorting and processing of demolished materials for recycling

- Proper disposal of any non-recyclable waste

- Site cleaning and preparation for subsequent construction or restoration

- Final environmental checks to ensure compliance with all regulations

- Comprehensive project documentation and reporting

This final phase ensures that the site is left clean, safe, and ready for its next use, while maximizing the recovery of valuable materials.

Types of Bridge Demolition Projects We Handle

Highway and Roadway Bridges

Our team has extensive experience demolishing highway overpasses, interchange bridges, and roadway spans. We understand the unique challenges these projects present, including traffic management, tight work windows, and the need for minimal disruption to transportation networks.

Railway Bridges

Railway bridge demolition requires specialized knowledge of rail infrastructure and often involves coordinating with railway authorities for track possession times. Our team has the expertise to safely demolish these structures while protecting adjacent tracks and minimizing service disruptions.

Pedestrian Bridges

While smaller in scale, pedestrian bridge demolition presents its own challenges, particularly in urban environments where public safety is paramount. We employ techniques that minimize noise and dust while ensuring complete safety for nearby pedestrians and properties.

Water-Crossing Structures

Bridges spanning rivers, canals, and other waterways require specialized approaches to prevent debris from entering the water and to protect aquatic ecosystems. Our team implements comprehensive containment systems and works closely with environmental authorities to ensure full compliance with regulations.

Partial Bridge Demolition and Modification

Not all projects require complete demolition. We also specialize in partial demolition for bridge widening, deck replacement, or structural modifications. These precision projects demand exceptional care to preserve the integrity of remaining structures.

Why Choose ASF Corporation for Your Bridge Demolition Project?

Technical Excellence

Our team brings unmatched technical expertise to every project, combining advanced engineering knowledge with practical field experience. This allows us to develop innovative solutions for even the most challenging demolition scenarios.

Comprehensive Service

From initial assessment through final site restoration, we provide end-to-end service for bridge demolition projects. This integrated approach ensures seamless coordination and accountability throughout the project lifecycle.

Commitment to Quality

Quality is embedded in every aspect of our operations. We maintain rigorous standards for workmanship, safety, and environmental protection, ensuring that each project meets or exceeds all relevant standards and specifications.

Local Knowledge, Global Standards

As a Bangladeshi company with international expertise, we combine deep local knowledge with world-class demolition practices. This unique perspective allows us to navigate local challenges while delivering results that meet the highest global standards.

Client-Centered Approach

We recognize that each client has unique needs and priorities. Our flexible, responsive approach ensures that we align our services with your specific requirements, providing personalized solutions rather than one-size-fits-all approaches.

Frequently Asked Questions

What methods are commonly used for bridge demolition?

The most common methods for bridge demolition include controlled demolition using explosives, mechanical demolition using heavy machinery like excavators and hydraulic breakers, and deconstruction which focuses on carefully dismantling the structure to salvage materials. Each method has specific advantages depending on the bridge type, location, and project requirements.

What safety measures are implemented during bridge demolition?

Safety measures include thorough site assessment before work begins, de-energizing and locking out all utilities, implementing fall protection systems (guardrails, safety netting), requiring appropriate personal protective equipment (PPE), establishing exclusion zones, monitoring structural stability throughout the process, and having qualified safety officers on-site to enforce protocols.

How is the environmental impact of bridge demolition managed?

Environmental impact is managed through dust suppression systems, proper containment measures for waterway protection, maximizing material recycling and reuse, implementing pollution control measures, and taking special precautions when bridges cross sensitive ecosystems. Projects near waterways require additional measures to prevent debris from contaminating water.

What happens to the materials after a bridge is demolished?

Most materials from demolished bridges are recycled. Concrete is typically crushed and reused as aggregate for new construction projects, while steel is sorted and sent to recycling facilities. This approach reduces landfill waste and aligns with sustainability goals. In deconstruction methods, materials may be specifically preserved for direct reuse.

How long does it typically take to demolish a bridge?

The duration varies significantly based on the bridge’s size, complexity, and the demolition method used. Small bridges might take only a few days to demolish, while larger structures could require several weeks. Controlled explosive demolition is the fastest method (the actual collapse takes seconds), while deconstruction is typically the most time-consuming.

What factors influence the choice of demolition method?

Factors include the bridge’s structural design, size, materials, age, and condition; the surrounding environment (urban vs. rural); proximity to other structures; environmental considerations; budget constraints; project timeline; traffic management requirements; and applicable regulations. Each project requires a tailored approach.

What permits and approvals are needed before bridge demolition?

Bridge demolition typically requires permits from local governments, transportation departments, and environmental agencies. Depending on the location, additional approvals may be needed from waterway authorities, railway companies, or other stakeholders. All legal requirements must be met before demolition can begin.

What are the first steps in the bridge demolition process?

The process begins with a comprehensive assessment of the bridge’s condition, structural design, and materials. This is followed by creating a detailed demolition plan, obtaining necessary permits, conducting environmental impact assessments, and implementing safety measures. Site preparation includes setting up safety barriers, rerouting traffic, and removing hazardous materials.

How are nearby structures and the public protected during demolition?

Protection measures include establishing exclusion zones (typically 250m radius for explosive demolition), implementing traffic management plans, installing debris netting systems, using dust suppression techniques, conducting thorough public notifications, and scheduling work during periods of minimal disruption. For explosive demolitions, the area is completely cleared before detonation.

What specialized equipment is used in bridge demolition?

Specialized equipment includes excavators with hydraulic breakers and concrete crushers, cranes for lifting heavy sections, concrete saws for precision cutting, thermal cutting tools for steel components, and in some cases, robotic demolition equipment for hazardous areas. For controlled demolition, precisely placed explosives are used to weaken key support structures.

Contact ASF Corporation Today

Ready to discuss your bridge demolition project? Our team is standing by to provide expert consultation and detailed proposals tailored to your specific needs.

ASF Corporation

Vashantek, Dhaka Cantonment

Dhaka-1206, Bangladesh

Phone: +88 01907-636827

Email: info@asfcorporation.com

Contact us today to schedule a consultation with our bridge demolition experts. Let ASF Corporation bring our expertise, commitment to safety, and environmental responsibility to your next infrastructure project.

Download Brochure

BENEFITS

Rigorous attention to detail ensuring accurate earthwork execution.

Application of cutting-edge technology for cost-effective operations.

Comprehensive service covering all aspects of mass earthworks.

Efficient and timely completion of tasks to keep your project on schedule.

Frequently Asked Questions (FAQ’s)

What is demolition in construction?

Demolition is the process of safely tearing down buildings, structures, or infrastructure, either partially or completely, to make way for new development or due to structural concerns.

What are the main types of demolition?

The main types include:

- Manual Demolition (hand tools)

- Mechanical Demolition (excavators, bulldozers)

- Implosion (controlled explosives)

Selective Demolition (partial removal)

When is demolition necessary?

Demolition is needed when a structure is unsafe, outdated, obstructive to new development, or being replaced by a new building.

What safety precautions are taken during demolition?

Safety measures include site assessments, securing the area, wearing protective gear, proper equipment use, and following local safety regulations and permits.

Do I need a permit for demolition?

Yes, most municipalities require a permit for demolition, and you must comply with local zoning laws, safety standards, and environmental guidelines.

How long does a demolition project take?

The duration depends on the structure’s size, type, and method used—ranging from a single day for small buildings to weeks or months for large or complex structures.

What happens to the debris after demolition?

Debris is sorted for recycling (e.g., metal, concrete), reuse, or proper disposal at approved landfills according to environmental regulations.

What is selective demolition?

Selective demolition involves removing specific parts of a structure—such as walls, floors, or fixtures—while preserving the rest for renovation or structural integrity.

Can demolition impact nearby buildings or residents?

Yes, demolition can cause dust, vibrations, and noise, which is why proper planning, communication, and protective measures are critical to minimize disruptions.

Demolition is the process of safely tearing down buildings, structures, or infrastructure, either partially or completely, to make way for new development or due to structural concerns.

The main types include:

- Manual Demolition (hand tools)

- Mechanical Demolition (excavators, bulldozers)

- Implosion (controlled explosives)

Selective Demolition (partial removal)

Demolition is needed when a structure is unsafe, outdated, obstructive to new development, or being replaced by a new building.

Safety measures include site assessments, securing the area, wearing protective gear, proper equipment use, and following local safety regulations and permits.

Yes, most municipalities require a permit for demolition, and you must comply with local zoning laws, safety standards, and environmental guidelines.

The duration depends on the structure’s size, type, and method used—ranging from a single day for small buildings to weeks or months for large or complex structures.

Debris is sorted for recycling (e.g., metal, concrete), reuse, or proper disposal at approved landfills according to environmental regulations.

Selective demolition involves removing specific parts of a structure—such as walls, floors, or fixtures—while preserving the rest for renovation or structural integrity.

Yes, demolition can cause dust, vibrations, and noise, which is why proper planning, communication, and protective measures are critical to minimize disruptions.