Bridge Construction

Sub-Service

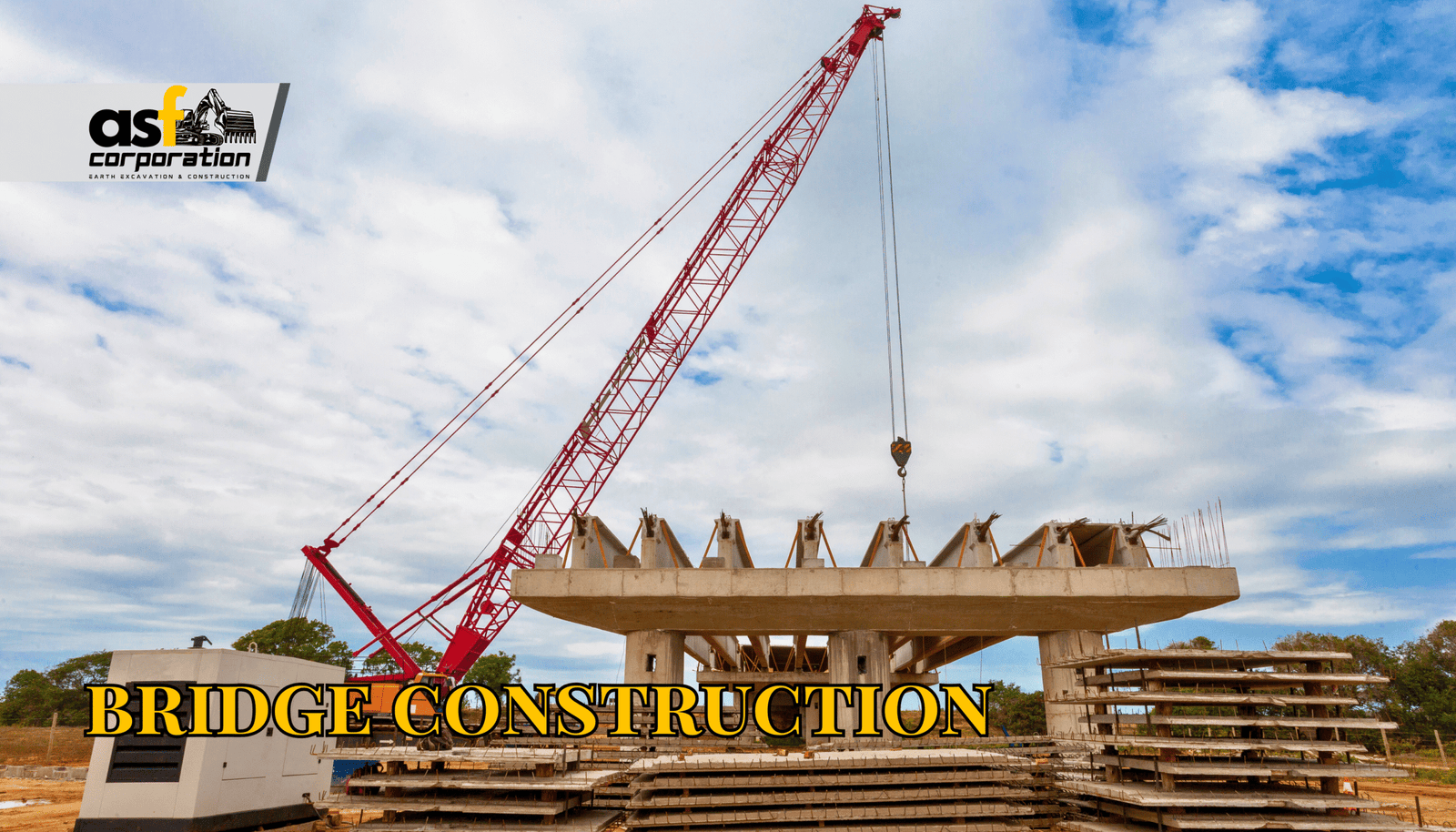

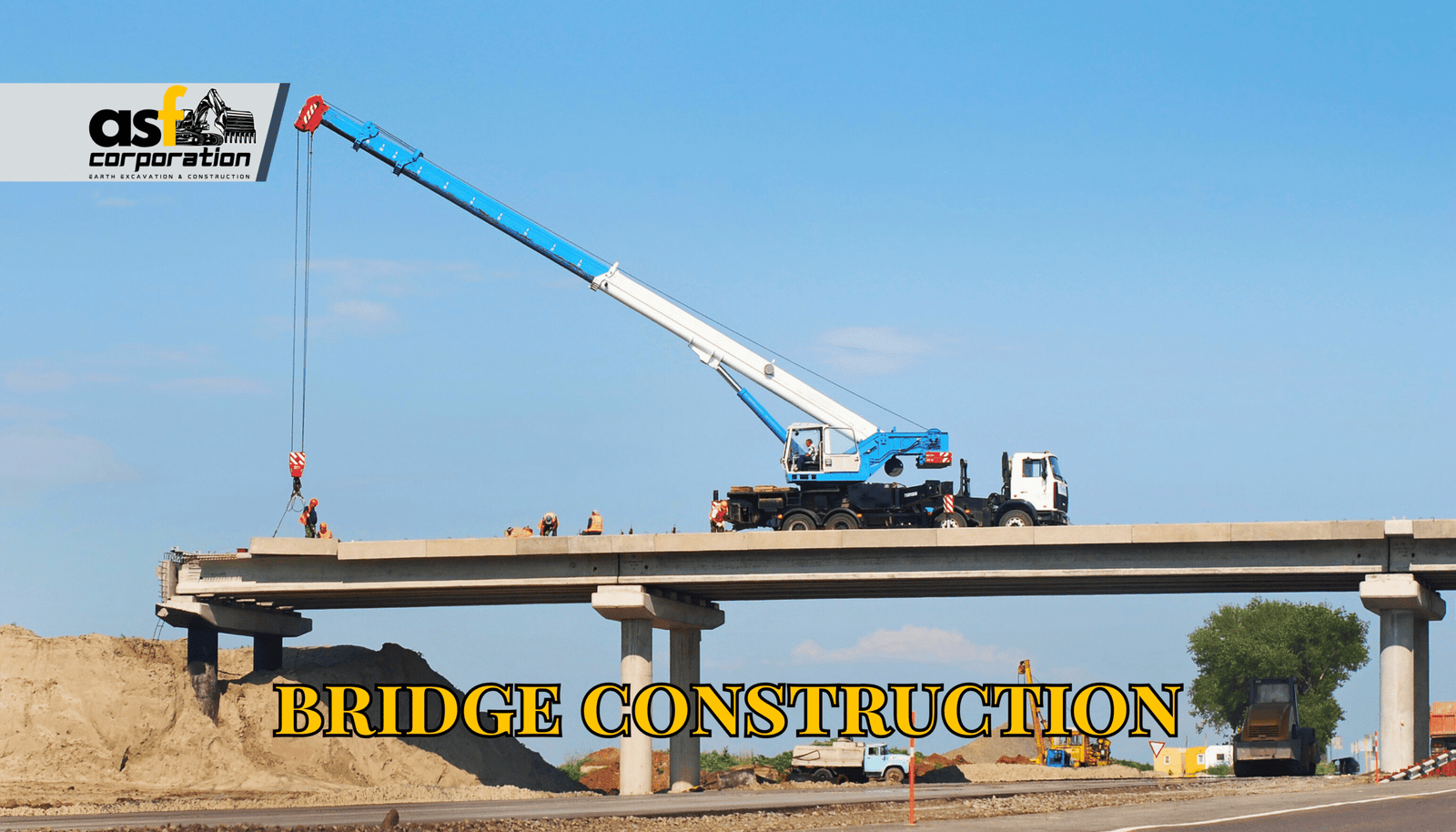

Bridge Construction Services by ASF Corporation

In the heart of Bangladesh’s infrastructure development, ASF Corporation stands as a premier provider of bridge construction services. With our headquarters in Vashantek, Dhaka Cantonment, we bring decades of expertise to every project, combining cutting-edge engineering with traditional craftsmanship to create bridges that connect communities and stand the test of time.

Safety First

Prioritizing protection and well-being to prevent accidents and ensure security.

Competitive Pricing

Offering attractive rates to stay attractive in the market and attract customers

Timely Completion

Finishing tasks on schedule, meeting deadlines, and ensuring efficient progress.

Our Bridge Construction Expertise

Bridge construction is a complex process requiring meticulous planning, engineering precision, and specialized equipment. At ASF Corporation, we handle every aspect of bridge development from initial concept to final inspection, ensuring structural integrity, safety, and longevity for all our projects across Dhaka and beyond.

Comprehensive Bridge Construction Process

Our methodical approach to bridge construction follows these essential stages:

Planning and Design: We begin with comprehensive planning and design, determining the bridge’s purpose, location, span length, anticipated loads, and site conditions. Our engineers conduct thorough feasibility studies considering community needs, traffic flow patterns, environmental conditions, and safety criteria.

Detailed Design: After establishing the initial concept, our team develops complete structural specifications, determining exact dimensions, performing strength calculations, and defining appropriate materials. We also outline long-term maintenance strategies to ensure maximum safety and functionality throughout the bridge’s lifespan.

Permit Acquisition: Before breaking ground, we handle all necessary regulatory approvals and permits, navigating Bangladesh’s construction regulations with expertise and efficiency.

Site Preparation: Our crews meticulously prepare construction sites, clearing vegetation, excavating ground, and establishing access roads and temporary facilities to ensure smooth operations throughout the project timeline.

Foundation Construction: We excavate and prepare foundation areas designed to support the bridge’s weight and structural requirements, creating a solid base for the entire structure.

Substructure Development: Our team builds piers, abutments, and support structures designed to carry the superstructure load according to precise engineering specifications.

Superstructure Erection: Once the substructure is complete and properly cured, we assemble and install girders, beams, or arches according to design specifications, creating the bridge’s main structural framework.

Deck Construction: We construct bridge decks using reinforced concrete, steel, timber, or composite materials based on project requirements, creating the surface that will serve as the roadway.

Finishing and Detailing: Our work includes installing expansion joints, safety railings, parapets, drainage systems, lighting, and other essential components that ensure functionality and safety.

Testing and Inspection: Before opening to traffic, we conduct rigorous inspections and load tests to verify structural integrity and compliance with all safety regulations and design requirements.

Bridge Construction Methods We Employ

ASF Corporation utilizes various construction methodologies tailored to each project’s unique requirements:

Traditional Construction Methods

Cast-in-Place Concrete: We build bridges on-site using concrete poured and cured in place, ideal for custom designs and challenging terrain.

Precast Concrete Construction: For faster completion times, we manufacture bridge components off-site in controlled environments, then transport and assemble them at the construction site.

Steel Construction: Our lightweight, durable steel bridges can be built quickly, with components fabricated off-site and assembled on location.

Advanced Construction Techniques

Cantilever Construction: For spanning wide rivers and deep valleys, we employ the spectacular cantilever technique, using the static principle of the balance beam to eliminate the need for falsework when conventional methods reach their technical and economic limits.

Incremental Launching: Our team expertly coordinates and executes incremental launching methods for bridges requiring specialized construction approaches.

Mobile Shoring with Integrated Formwork: We utilize advanced mobile shoring systems with integrated formwork to enhance efficiency and precision.

Types of Bridges We Construct

ASF Corporation has the expertise to build various bridge types to meet specific project requirements:

Reinforced Concrete Bridges: Utilizing loose reinforcement for strength and durability in standard applications.

Prestressed Bridges: Employing prestressing techniques to enhance structural performance and span capabilities.

Cable-Stayed Bridges: Constructing sophisticated cable-stayed structures for longer spans with distinctive architectural appeal.

Composite Steel Bridges: Combining steel and concrete elements to optimize strength-to-weight ratios and construction efficiency.

Timber Bridges: Building environmentally friendly wooden bridges for appropriate applications and settings.

Suspension Bridges: Erecting towers on-site while fabricating main cables and suspenders off-site for efficient assembly of these iconic structures.

Bridge Maintenance and Rehabilitation

Beyond new construction, ASF Corporation specializes in extending the life of existing bridges through comprehensive maintenance and rehabilitation services:

Bridge Deck Repairs and Waterproofing: Restoring and protecting bridge deck surfaces to prevent water damage and deterioration.

Bridge Strengthening: Implementing structural reinforcements to increase load capacity and extend service life.

Bearing Replacement and Refurbishment: Servicing or replacing bridge bearings to ensure proper load distribution and movement accommodation.

Paint and Coating Repairs: Applying protective coatings to prevent corrosion and environmental damage.

Masonry Repairs: Restoring historical and stone bridges with specialized masonry techniques.

Parapet Repairs or Replacement: Ensuring safety barriers meet current standards and provide adequate protection.

Our Specialized Access Capabilities

ASF Corporation excels at accessing challenging bridge construction environments through various specialized methods:

Rope Access: Our certified technicians can reach difficult areas safely without extensive scaffolding.

Confined Space Operations: Our teams are trained and equipped for work in restricted spaces.

Water-Based Access: We utilize pontoons and boats for bridges spanning waterways.

Elevated Work Platforms: Our fleet includes MEWPs and other powered access equipment for efficient high-level work.

Custom Access Solutions: We develop bespoke access systems for uniquely challenging situations.

Why Choose ASF Corporation for Bridge Construction?

Local Expertise with Global Standards

Based in Dhaka Cantonment, ASF Corporation brings intimate knowledge of Bangladesh’s unique geographical, environmental, and regulatory landscape to every project. Our local expertise is complemented by adherence to international bridge construction standards, ensuring world-class quality in every structure we build.

Comprehensive Project Management

From initial concept through completion, our experienced project managers oversee every aspect of bridge construction, ensuring adherence to timelines, budgets, and quality standards. We coordinate with all stakeholders, from government agencies to local communities, to ensure smooth project execution with minimal disruption.

Commitment to Safety

Safety is paramount in all ASF Corporation operations. Our rigorous safety protocols exceed industry standards, protecting our workers, the public, and the environment throughout the construction process. Every team member receives comprehensive safety training, and we maintain strict oversight at all project sites.

Environmental Responsibility

We recognize the environmental impact of bridge construction and implement sustainable practices throughout our operations. From minimizing habitat disruption during site preparation to incorporating eco-friendly materials where appropriate, ASF Corporation strives to balance infrastructure development with environmental stewardship.

Cutting-Edge Technology

ASF Corporation utilizes the latest engineering software, construction equipment, and materials to enhance efficiency, precision, and durability in our bridge projects. Our investment in technology translates to better bridges built more efficiently.

Quality Assurance

Our quality control processes ensure that every component meets or exceeds specifications. Through regular inspections, material testing, and adherence to international standards, we guarantee the structural integrity and longevity of every bridge we construct.

Our Portfolio

ASF Corporation has successfully completed numerous bridge projects throughout Bangladesh, including:

- Highway bridges using reinforced concrete, steel, and composite construction

- Pedestrian and cycling bridges in urban and rural settings

- Heritage structure restorations and rehabilitations

- Bridges spanning major waterways, railways, and highways

- Emergency bridge replacements and repairs

Each project in our portfolio demonstrates our commitment to excellence, innovation, and durability in bridge construction.

Frequently Asked Questions

What are the common types of bridge foundations used in Bangladesh?

In Bangladesh, three main types of deep foundations are commonly used for bridge construction in riverbeds: caissons, cast-in-situ bored piles, and tubular bored piles (with or without concrete infill). For larger bridges, large diameter (1200mm) cast-in-situ RCC bored piles are quite common, while viaduct spans typically use 1000mm diameter cast-in-situ bored piles.

What challenges are faced during bridge construction in Bangladesh?

Bridge construction in Bangladesh faces several challenges including complex soil distribution across river crossings, heterogeneous soil conditions in both vertical and horizontal directions, predominance of silt-sized materials containing significant percentages of mica, unstable riverbanks, and rapid river scour that can significantly change the cross-section and course of rivers.

How long does a typical bridge construction project take in Bangladesh?

Based on past projects, bridge construction in Bangladesh typically takes around 3-4 years. For example, the bridge project at 70th Km on Labukhali-Dumki-Boga-Dashmina-Golachipa-Amragachi Road had a planned construction period of 4 years (2014 to 2017).

What government authority oversees bridge construction in Bangladesh?

The Bangladesh Bridge Authority (BBA) is the primary government organization responsible for overseeing major bridge construction projects in the country. It was established in 1985 for carrying out the purposes outlined in the Bangladesh Bridge Authority Ordinance.

What is the role of river training works in bridge construction?

River training works and guide bunds are essential components of bridge construction in Bangladesh to confine river flow within the bridge length. These structures require bank protection from waves, bed scour, and ensure slope stability. Guide bunds typically comprise heavily protected sand slopes designed to control the flow of rivers.

How are bridge foundations designed to withstand Bangladesh’s river conditions?

Bridge foundations in Bangladesh are designed considering the local soil conditions, hydraulic flow, and scour potential. For large bridges, techniques such as skin and base grouting are employed to improve pile capacity. Special considerations are given to the presence of mica in soils and the potential for rapid scour in the loose alluvial soils typical of Bangladesh’s rivers.

What testing methods are used to verify bridge foundation strength?

For large bridges in Bangladesh, Osterberg (O-cell) tests have been performed to interpret pile capacity and derive skin frictional resistance and base resistance of large diameter piles. These tests have revealed that considerable improvement in pile capacity can be achieved through skin and base grouting techniques.

What economic benefits do bridge projects typically bring to communities?

Bridge projects in Bangladesh typically provide significant economic benefits including increased economic activity, enhanced educational opportunities, and overall regional development. For example, the bridge project at 70th Km on Labukhali-Dumki-Boga-Dashmina-Golachipa-Amragachi Road was projected to have a Benefit-Cost Ratio (BCR) of 1.30 and an Economic Internal Rate of Return (EIRR) of 18.64%.

How are environmental impacts assessed for bridge construction projects?

Environmental impacts of bridge construction are assessed through specific mitigative and monitoring measures. Projects undergo environmental impact assessments to ensure they will not lead to any long-term irreversible adverse impacts on adjacent environmental quality. These assessments are part of the feasibility study phase of bridge projects.

What maintenance challenges do bridges face after construction in Bangladesh?

Bridges in Bangladesh face maintenance challenges related to scour, slope stability of approach roads, and deterioration due to environmental conditions. The Roads and Highway Department (RHD) has developed Bridge Maintenance Management Standards to address these issues, though finding professional Bridge Inspectors in Bangladesh remains difficult due to poor marketability of this profession.

Contact ASF Corporation for Your Bridge Construction Needs

Ready to discuss your bridge construction project? ASF Corporation offers free consultations to assess your needs and provide expert recommendations. Our team is ready to bring your infrastructure vision to life with precision, efficiency, and excellence.

Visit Our Office:

ASF Corporation

Vashantek, Dhaka Cantonment

Dhaka-1206, Bangladesh

Call Us Today:

+88 01907-636827

Email Us:

info@asfcorporation.com

Request Your Free Bridge Construction Consultation Now

Let ASF Corporation be your partner in building bridges that connect communities and stand the test of time. Contact us today to discuss how our expertise can bring your infrastructure project to successful completion.

Download Brochure

BENEFITS

Rigorous attention to detail ensuring accurate earthwork execution.

Application of cutting-edge technology for cost-effective operations.

Comprehensive service covering all aspects of mass earthworks.

Efficient and timely completion of tasks to keep your project on schedule.

Frequently Asked Questions (FAQ’s)

What is construction?

Construction is the process of building, assembling, or installing infrastructure such as buildings, roads, bridges, and pipelines. It involves planning, design, financing, and execution of various projects.

What are the main types of construction?

The main types include:

- Residential construction (homes, apartments)

- Commercial construction (offices, retail spaces)

- Industrial construction (factories, plants)

- Infrastructure/heavy civil construction (roads, bridges, pipelines)

What professionals are involved in a construction project?

Key professionals include:

- Architects

- Civil engineers

- Structural engineers

- Project managers

- Construction workers

- Surveyors

Electricians and plumbers (for specialized systems)

What are the typical phases of a construction project?

- Planning and design

- Pre-construction

- Procurement

- Construction

Post-construction (inspection, handover, maintenance)

What safety measures are essential in construction?

- Use of personal protective equipment (PPE)

- Site safety training

- Equipment maintenance

- Safety signage and barriers

- Regular inspections and hazard assessments

What causes delays in construction projects?

Common causes include:

- Poor planning or design changes

- Weather conditions

- Labor or material shortages

- Regulatory or permit issues

Equipment breakdowns

How is construction financed?

Construction projects are typically funded through:

- Private investment

- Bank loans or mortgages

- Government funding (for public infrastructure)

Public-private partnerships (PPPs)

What is sustainable construction?

Sustainable construction involves environmentally responsible building practices, such as:

- Using energy-efficient materials

- Minimizing waste

- Incorporating renewable energy sources

- Designing for long-term sustainability

What technologies are transforming the construction industry?

- Building Information Modeling (BIM)

- Drones for surveying and monitoring

- 3D printing of building components

- Robotics and automation

- Green building materials

- Construction management software

Construction is the process of building, assembling, or installing infrastructure such as buildings, roads, bridges, and pipelines. It involves planning, design, financing, and execution of various projects.

The main types include:

- Residential construction (homes, apartments)

- Commercial construction (offices, retail spaces)

- Industrial construction (factories, plants)

- Infrastructure/heavy civil construction (roads, bridges, pipelines)

Key professionals include:

- Architects

- Civil engineers

- Structural engineers

- Project managers

- Construction workers

- Surveyors

Electricians and plumbers (for specialized systems)

- Planning and design

- Pre-construction

- Procurement

- Construction

Post-construction (inspection, handover, maintenance)

- Use of personal protective equipment (PPE)

- Site safety training

- Equipment maintenance

- Safety signage and barriers

- Regular inspections and hazard assessments

Common causes include:

- Poor planning or design changes

- Weather conditions

- Labor or material shortages

- Regulatory or permit issues

Equipment breakdowns

Construction projects are typically funded through:

- Private investment

- Bank loans or mortgages

- Government funding (for public infrastructure)

Public-private partnerships (PPPs)

Sustainable construction involves environmentally responsible building practices, such as:

- Using energy-efficient materials

- Minimizing waste

- Incorporating renewable energy sources

- Designing for long-term sustainability

- Building Information Modeling (BIM)

- Drones for surveying and monitoring

- 3D printing of building components

- Robotics and automation

- Green building materials

- Construction management software