In the world of construction and structural engineering, few elements are as crucial yet often overlooked as bracing methods. These vital structural components serve as the unsung heroes that keep our buildings standing tall against the forces of nature. Whether you’re constructing a residential building, commercial space, or industrial facility, implementing proper bracing systems can mean the difference between a structure that withstands the test of time and one that fails when challenged by lateral forces.

What is a Bracing System?

A bracing system is a structural element designed to resist lateral forces such as wind, seismic activity, and other loads that could potentially cause a building to sway or collapse. These systems work by providing additional support to the main structural framework, enhancing overall stability and ensuring that buildings maintain their integrity even under extreme conditions.

Bracing methods are essential components in modern construction, particularly in areas prone to high winds or seismic activity. They function by distributing loads across the structure, preventing excessive movement and potential structural failure.

Types of Bracing Systems

The world of structural engineering offers various bracing methods, each designed to address specific structural needs and challenges. Understanding these different types can help engineers and construction professionals select the most appropriate system for their projects.

Vertical Bracing

Vertical bracing systems are specifically designed to enhance the stability of buildings, particularly tall structures like skyscrapers. These braces run vertically along the height of the building, effectively resisting and transferring loads from upper levels down to the foundation. This type of bracing is especially critical in regions prone to high winds or seismic activity, where lateral forces can significantly impact structural integrity.

Horizontal Bracing

Horizontal bracing connects and stabilizes the vertical elements of a structure. Running parallel to the ground, these bracing systems are typically integrated within floors or along the roofs of buildings. Their primary function is to distribute lateral forces evenly across the structure, preventing excessive movement that could lead to structural failures. Horizontal bracing works in conjunction with vertical systems to create a comprehensive structural support network.

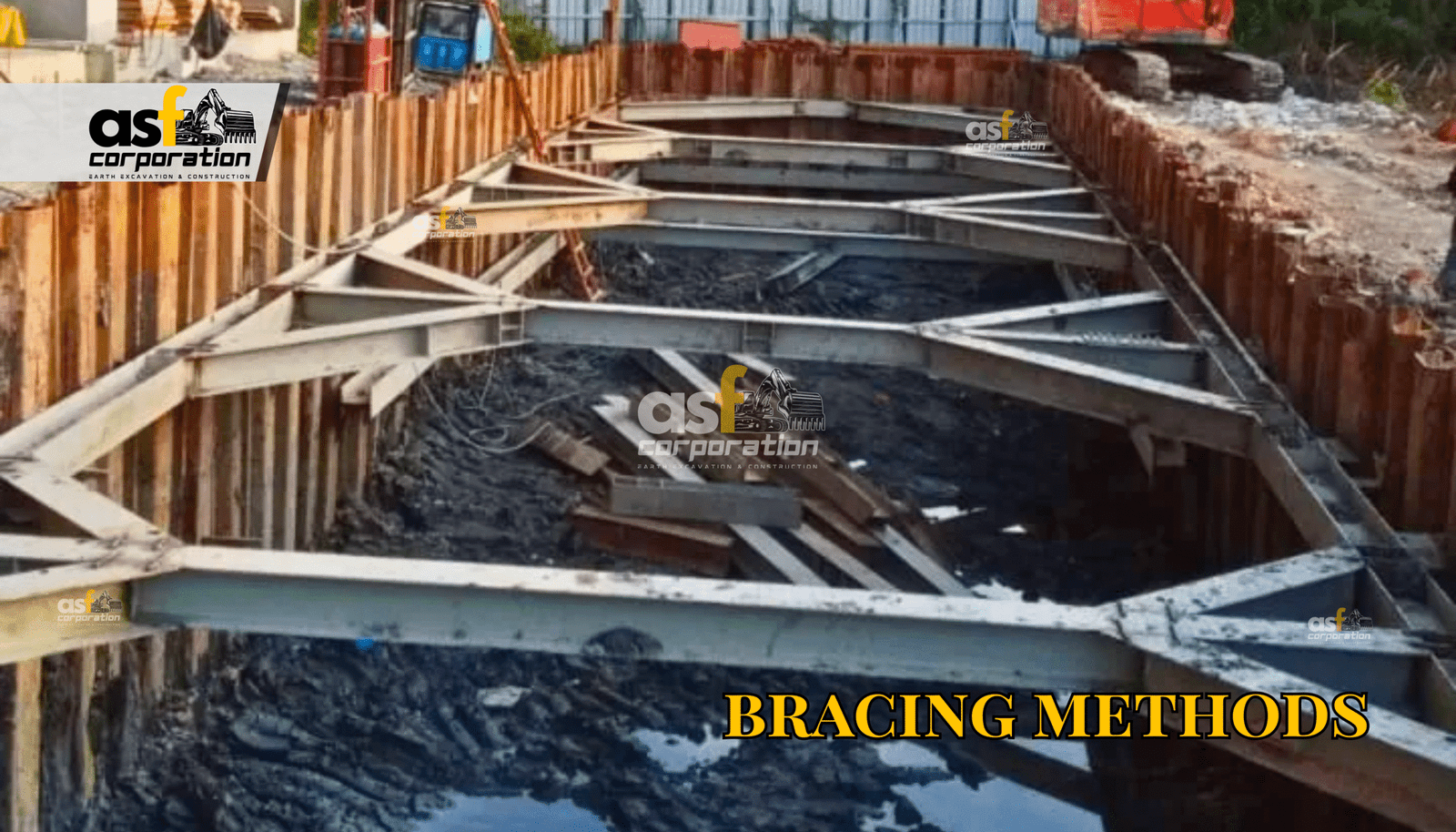

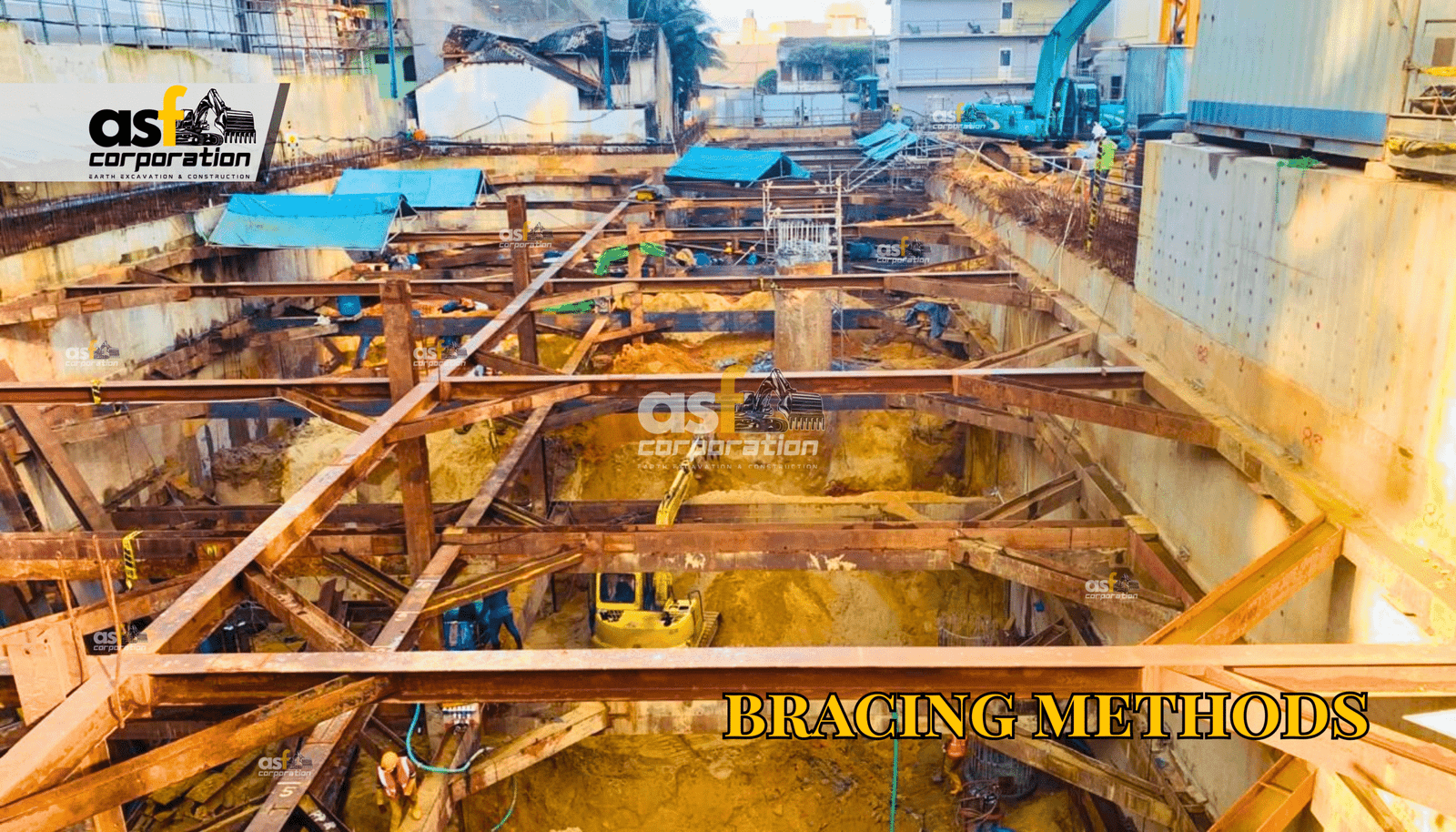

Diagonal Bracing

Diagonal bracing involves strategically placing braces at angles between vertical supports. This arrangement is highly effective for increasing structural rigidity by bracing against angular shifts and deformations. There are several subtypes of diagonal bracing:

K-Bracing: This method resembles the letter “K” and can be mounted either vertically or horizontally. Commonly used in steel buildings, K-bracing increases resistance to both lateral and vertical forces, enhancing the building’s overall structural integrity.

X-Bracing: Similar to K-bracing, X-bracing forms an “X” shape and is typically found in steel constructions. This versatile system can be mounted vertically or horizontally, providing stability against both lateral and vertical stresses.

Other Bracing Types

Shear Walls: These vertical components are specifically designed to withstand lateral stresses. Typically constructed from concrete or masonry, shear walls work in conjunction with other bracing systems to increase the overall structural strength of a building. They function by transmitting lateral stresses to the foundation, offering stability and reducing structural deformations.

Core Walls: Core walls provide central structural support and are often incorporated into the design of high-rise buildings. They typically house elevator shafts and stairwells while simultaneously serving as major structural elements.

Plan Bracing: This type directly prevents lateral buckling of compression flanges by stopping them from moving sideways. Plan bracing typically consists of diagonal members, usually angle sections, that connect the compression flanges of main beams to form a truss when viewed from above.

Torsional Bracing: This form of bracing creates a plane between a pair of beams, making them function as a stable unit. While it doesn’t provide direct lateral restraint to compression flanges, torsional bracing forces both beams to twist as a single unit, increasing resistance to buckling.

The Science Behind Bracing Methods

Understanding how bracing systems work requires knowledge of structural engineering principles. When lateral forces act on a building, they create moments that can cause the structure to sway or, in extreme cases, collapse. Bracing systems counteract these forces by:

- Directing lateral loads in horizontal beams and diaphragms to angled struts, leveraging the axial strength of brace members and providing load paths that transfer lateral loads into vertical elements and down to foundations.

- Reducing deflection and sway caused by lateral loading by stiffening parts of the structure. This could involve roof diaphragms, belt and braces outriggers, or vertical walls.

- Controlling global buckling and torsion by providing steel bracing systems on at least three of the four sides of a building. For local buckling and torsion of steel bracing, implementing direct lateral restraint for compression flanges or torsional restraint to the whole beam is essential.

Advantages of Bracing Methods

Implementing proper bracing systems in construction projects offers numerous benefits that contribute significantly to the overall quality, safety, and longevity of structures.

Enhanced Structural Stability

Perhaps the most significant advantage of bracing methods is the substantial improvement in structural stability. Bracing systems significantly increase a structure’s resistance to lateral forces such as wind and seismic activities. This enhanced stability helps prevent structural damage and failure, contributing to the building’s longevity, which is particularly crucial for high-rise buildings and structures in earthquake-prone areas.

Improved Safety

By reinforcing a building’s framework, bracing systems ensure that structures are safer for occupants. This is especially important in areas subject to extreme environmental conditions, as it minimizes the risk of collapse and maximizes occupant safety during natural disasters. Bracing systems prevent collapse or significant structural damage during extreme events like earthquakes or high winds.

Cost-Effectiveness

Compared to other structural reinforcement methods, bracing systems offer a more economical solution for enhancing building rigidity. They require fewer materials and labor, which helps manage construction costs effectively while achieving desired safety and stability standards. Additionally, implementing bracing systems can lead to long-term cost savings by reducing the need for extensive structural repairs or reinforcements.

Efficient Material Use

Bracing systems are designed to use materials efficiently, distributing stresses across the structure to prevent overloading any single component. This efficient use of materials supports sustainability efforts and ensures that buildings can handle unexpected loads without requiring extensive modifications.

Quick Installation

Many bracing systems are designed for rapid installation, which can significantly reduce overall construction timelines. This speedier process helps achieve quicker project completion, reduces labor costs, and minimizes disruptions caused by prolonged construction activities.

Architectural Flexibility

Advanced bracing options like moment frames allow architects and designers more freedom in their designs. These systems support larger open spaces within buildings, facilitating modern architectural aesthetics and functional layouts without compromising structural integrity.

Challenges and Considerations

While bracing methods offer numerous advantages, they also present certain challenges that must be addressed during the design and implementation phases.

Design Constraints

Incorporating bracing systems may limit design flexibility in some aspects, particularly when visible bracing elements affect the aesthetic appearance of a building. Engineers and architects must balance structural requirements with design considerations to achieve both safety and visual appeal.

Maintenance Requirements

Like all structural elements, bracing systems require regular inspection and maintenance to ensure continued effectiveness. This ongoing maintenance represents an additional cost and responsibility for building owners and managers.

Installation Complexity

Some bracing methods, particularly in complex structures, may require specialized knowledge and skills for proper installation. This complexity can increase initial construction costs and timelines if not properly managed.

Designing Effective Bracing Systems

Creating an effective bracing system involves several key considerations:

- Identify suitable intermediate bracing positions (and their stiffness) for the adequacy of the main beams.

- Design the intermediate bracing to handle the expected loads and forces.

- Design the support bracing to ensure proper load transfer to the foundation.

The design process typically involves calculating the non-dimensional slenderness from which the design bending resistance can be determined using appropriate engineering standards. For complex structures, comprehensive 3D structural models may be necessary to accurately predict how bracing systems will perform under various load conditions.

Bracing Methods in Modern Construction

Modern construction practices continue to evolve, with bracing methods becoming increasingly sophisticated. Innovations in materials and design approaches have led to more efficient and effective bracing systems that can address the challenges of contemporary architecture while maintaining structural integrity.

Advanced computer modeling and analysis tools now allow engineers to optimize bracing designs, ensuring they provide maximum stability with minimal material usage. This optimization not only reduces costs but also supports sustainability goals by minimizing resource consumption.

Choosing the Right Bracing Method for Your Project

Selecting the appropriate bracing method depends on various factors, including:

- Building height and dimensions

- Expected lateral loads (wind, seismic activity)

- Architectural requirements and constraints

- Budget considerations

- Local building codes and regulations

- Construction timeline

Working with experienced structural engineers is essential to determine the most suitable bracing approach for your specific project needs.

The Future of Bracing Methods

As construction technology advances, we can expect to see continued innovation in bracing methods. Emerging trends include:

- Integration of smart materials that can adapt to changing load conditions

- Development of more aesthetically pleasing bracing systems that complement architectural designs

- Implementation of modular bracing components that can be quickly installed and modified as needed

- Increased use of composite materials that offer superior strength-to-weight ratios

These innovations will likely make bracing systems even more effective, efficient, and versatile in the years to come.

Conclusion:

Bracing methods represent a critical aspect of structural engineering that directly impacts the safety, stability, and longevity of our built environment. By understanding the various types of bracing systems and their applications, construction professionals can make informed decisions that enhance structural performance while meeting design and budget requirements.

Whether you’re planning a new construction project or evaluating an existing structure, giving proper attention to bracing methods is essential for ensuring long-term structural integrity and occupant safety. The right bracing system not only protects your investment but also contributes to the resilience of our built environment in the face of increasingly unpredictable natural forces.

Frequently Asked Questions

What is structural bracing and why is it important?

Structural bracing refers to the systems used to reinforce buildings against lateral forces like wind and earthquakes. It’s crucial because it prevents buildings from swaying, maintains structural integrity, and ensures occupant safety during extreme weather events or seismic activity.

What are the most common types of bracing methods used in construction?

The most common bracing methods include X-bracing, K-bracing, diagonal bracing, horizontal bracing, vertical bracing, shear walls, and moment frames. Each serves specific structural needs depending on the building type and expected lateral forces.

How do I know which bracing method is right for my construction project?

The appropriate bracing method depends on several factors including building height, expected lateral loads, architectural requirements, budget constraints, and local building codes. Consulting with a structural engineer is essential to determine the most suitable approach for your specific project.

Can bracing systems be incorporated into existing structures?

Yes, retrofitting existing structures with bracing systems is possible and often necessary for older buildings to meet current safety standards. However, this process requires careful structural analysis and may involve more complex installation procedures than implementing bracing in new construction.

How do bracing methods affect the architectural design of a building?

Some bracing methods, particularly diagonal and X-bracing, can impact the architectural aesthetics and space utilization of a building. However, modern approaches like moment frames offer more design flexibility while still providing necessary structural support.

What maintenance do bracing systems require?

Bracing systems should be inspected regularly for signs of corrosion, connection loosening, or damage. The frequency of inspection depends on the building’s location, age, and exposure to environmental conditions. Any identified issues should be addressed promptly by qualified professionals.

How do bracing methods perform during earthquakes?

Well-designed bracing systems significantly improve a building’s performance during seismic events by absorbing and distributing the energy from ground movements. Different bracing types offer varying levels of seismic resistance, with some specifically engineered for high seismic zones.

What is the cost difference between various bracing methods?

Costs vary widely depending on the bracing type, materials used, and complexity of installation. Generally, conventional methods like diagonal bracing tend to be more economical, while specialized systems like moment frames may require higher initial investment but offer other benefits like architectural flexibility.

Can sustainable or eco-friendly materials be used in bracing systems?

Yes, sustainable materials can be incorporated into bracing designs. Options include responsibly sourced timber, recycled steel, and innovative composite materials. The sustainability aspect should be balanced with structural performance requirements.

How have bracing methods evolved with modern construction technology?

Modern bracing methods have benefited from advances in materials science, computer modeling, and construction techniques. Today’s systems are more efficient, offering better performance with less material. Innovations include smart bracing systems that can adapt to changing loads and prefabricated components that speed up installation.

Need Expert Guidance on Bracing Methods?

At ASF Corporation, we specialize in providing comprehensive structural engineering solutions, including advanced bracing system design and implementation. Our team of experienced engineers understands the critical role that proper bracing plays in structural stability and safety.

Whether you’re planning a new construction project or need to evaluate the bracing systems in an existing structure, we’re here to help. Our expertise ensures that your building will stand strong against lateral forces while meeting all relevant building codes and regulations.

Contact us today to discuss your project needs and discover how our bracing vendor expertise can contribute to the success of your construction endeavors.

ASF Corporation

Vashantek, Dhaka Cantonment

Dhaka-1206, Bangladesh

Phone: +88 01907-636827

Email: info@asfcorporation.com

Let us help you build structures that stand the test of time with proper bracing methods