Cast In Situ Pile

Sub-Service

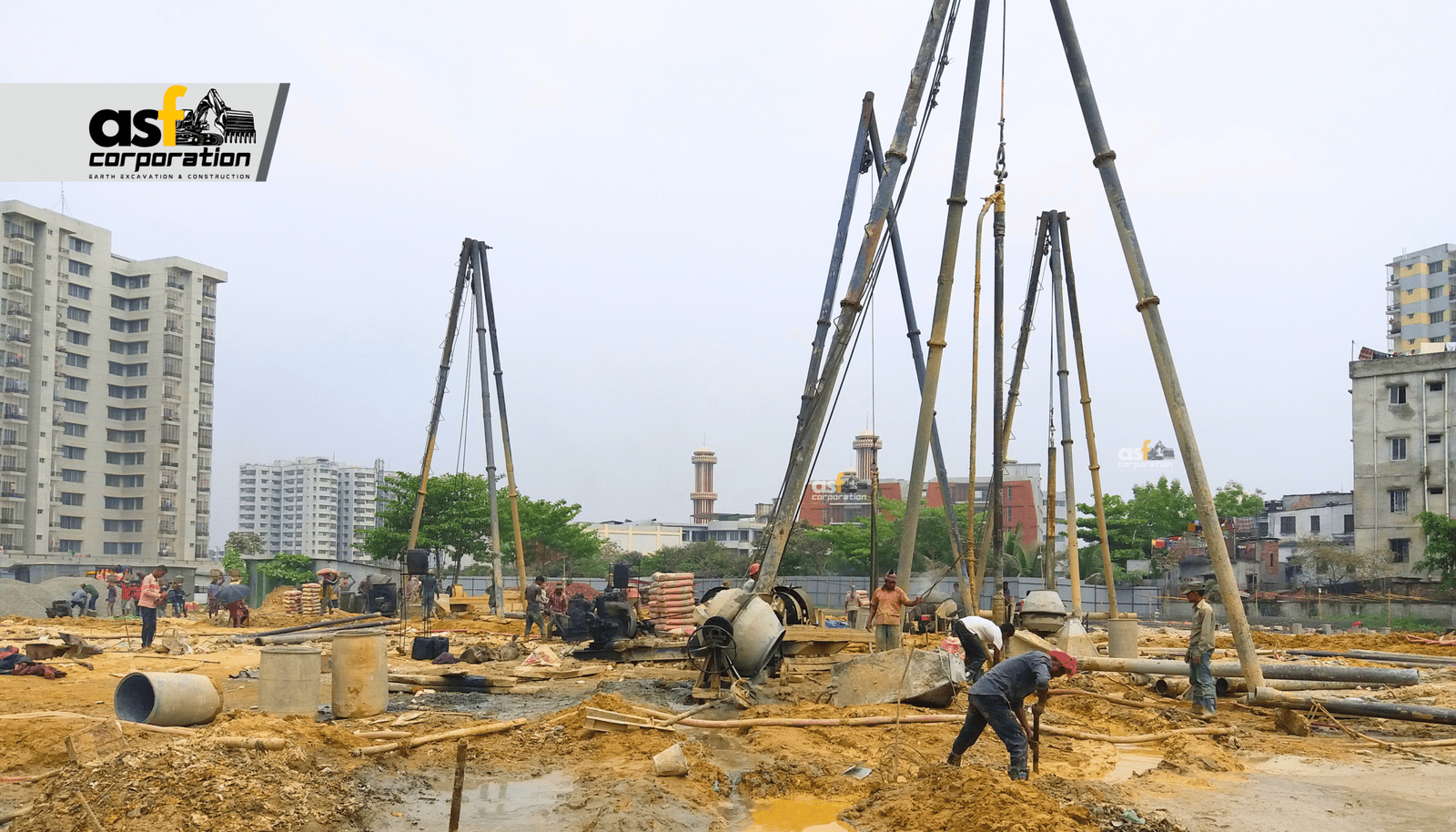

Cast In Situ Pile: Creating Strong Foundations for Your Construction Projects

Are you planning a construction project in Dhaka that requires a solid foundation? Cast in situ pile might be exactly what you need. At ASF Corporation, we specialize in providing expert cast in situ pile services that ensure your structures stand strong for decades to come. Our team of experienced professionals delivers reliable, cost-effective foundation solutions tailored to the unique soil conditions of Bangladesh.

Safety First

Prioritizing protection and well-being to prevent accidents and ensure security.

Competitive Pricing

Offering attractive rates to stay attractive in the market and attract customers

Timely Completion

Finishing tasks on schedule, meeting deadlines, and ensuring efficient progress.

What Are Cast In Situ Pile?

Cast in situ pile are concrete pile that are constructed by excavating soil and pouring concrete directly into the hole at the construction site. Unlike precast piles that are manufactured elsewhere and transported to the site, cast in situ pile are formed right where they’ll serve their purpose – creating a seamless, monolithic foundation structure that offers exceptional strength and stability.

These foundation elements are essential when the upper layers of soil are too weak or unstable to support the weight of a structure on their own. By transferring the load to more stable soil or rock layers beneath the surface, cast in situ pile provide the solid base your building needs to withstand both vertical loads and lateral forces.

Types of Cast In Situ Pile We Offer

At ASF Corporation, we provide various types of cast in situ pile solutions to meet the specific requirements of your construction project:

Simplex Pile: The most common type used in Bangladesh, simplex pile involve installing a casing that is reinforced with rebar before concrete is poured while the casing is vibrated out of the ground.

Bored Cast In Situ Pile: These piles are created by drilling a hole into the ground using specialized equipment, placing reinforcement, and then filling with concrete. They’re ideal for sites where noise restrictions apply or where there are existing structures nearby.

Under-Reamed Piles: These feature an enlarged base that provides additional bearing capacity, making them perfect for expansive soils common in certain areas of Dhaka.

Each type has specific applications and advantages, and our engineering team will recommend the most suitable option based on your project’s requirements and site conditions.

Our Cast In Situ Pile Construction Process

At ASF Corporation, we follow a methodical, proven approach to cast in situ pile installation that ensures quality, durability, and structural integrity. Our comprehensive process includes:

Site Investigation and Analysis

Before any work begins, we conduct a thorough site investigation to assess soil conditions, groundwater levels, and other factors that will influence the design and installation of your piles. This critical first step includes soil borings, test pits, and detailed geotechnical analysis to determine the optimal pile design for your specific site.

Design and Planning

Based on the site investigation results, our engineers design a customized foundation piling system, determining the appropriate type, size, and length of piles, as well as their optimal placement and load-bearing capacity. We also plan for any potential challenges, such as underground utilities or environmental considerations.

Boring the Pile Hole

Our team sets up hydraulic rigs or manual augers at precisely marked locations and begins boring to the required depth according to the sub-soil report. We use temporary guide casings and bentonite slurry as needed to maintain borehole stability throughout the process.

Reinforcement Cage Installation

We prepare and install prefabricated reinforcement cages according to approved construction drawings. Circular cover blocks ensure proper concrete cover, and for longer cages, sections are carefully connected and measured to ensure they reach the borehole bottom.

Hole Cleaning

After lowering the reinforcement cage, we place tremie pipes in the hole and circulate fresh bentonite slurry to flush the bore until all loose sediments are removed. This crucial step ensures a clean foundation for concrete placement.

Concrete Pouring

Using the tremie method, we pour high-quality concrete into the borehole, maintaining a continuous pour to prevent water or debris infiltration. The concrete is placed at least 300mm above the cut-off level to ensure integrity throughout the pile.

Quality Testing

Once the concrete has cured, we conduct comprehensive testing to verify the integrity and load-bearing capacity of the piles, ensuring they meet all design specifications and industry standards.

Advantages of Choosing Our Cast In Situ Pile Services

When you choose ASF Corporation for your cast in situ pile needs, you benefit from numerous advantages:

Superior Strength and Stability: Cast in situ piles create a monolithic structural system that significantly enhances your building’s strength. With proper steel reinforcement, these structures offer excellent resistance to both compressive and tensile forces, providing extraordinary resistance to shear and seismic forces.

Cost-Effectiveness: Our cast in situ pile solutions are economically advantageous, with forms that can be repeatedly reused, resulting in significant financial savings. The process requires only basic concrete products without specialized equipment, further reducing costs.

Adaptability to Site Conditions: Cast in situ piles are ideal for sites with variable ground conditions or existing obstructions that could damage pre-formed piles. They can be easily modified in length during installation to adapt to unexpected soil conditions.

Quality Assurance: Our piles can be inspected internally before concrete pouring to ensure the soil is suitable for the foundation. Once poured, the concrete remains undisturbed by external forces, maintaining structural integrity.

Reduced Environmental Impact: By eliminating the need to transport precast elements to the site, cast in situ piles reduce carbon emissions associated with your project.

Applications of Cast In Situ Pile

Our cast in situ pile service are versatile and can be applied to various construction projects throughout Dhaka and beyond:

- Foundations for new residential and commercial buildings

- Infrastructure projects and floor slabs

- Bridge abutments, piers, and load transfer platforms

- High-rise buildings and towers

- Industrial complexes requiring heavy load support

- Sites with challenging soil conditions

Why Choose ASF Corporation for Your Cast In Situ Pile Needs?

Local Expertise

Based in Vashantek, Dhaka Cantonment, we have extensive knowledge of local soil conditions and construction requirements specific to Bangladesh. Our team understands the unique challenges posed by Dhaka’s soil profile and designs foundation solutions accordingly.

Experienced Team

Our diverse team includes civil engineers, geotechnical engineers, structural engineers, project managers, and quality control specialists who work collaboratively to deliver exceptional results. Each professional brings specialized knowledge to ensure your project’s success.

Advanced Equipment and Techniques

We utilize state-of-the-art drilling equipment and modern construction techniques to ensure efficient, precise pile installation. Our investment in technology translates to better quality and faster project completion for you.

Commitment to Quality

Quality control is at the heart of our operations. We implement rigorous testing and inspection protocols throughout the construction process to ensure every pile meets or exceeds industry standards and design specifications.

Sustainable Practices

We’re committed to environmentally responsible construction practices, optimizing material usage and implementing efficient drilling techniques to minimize waste and reduce environmental impact.

Competitive Pricing

We provide transparent, competitive pricing without compromising on quality. Our efficient processes and local sourcing of materials allow us to offer excellent value for your investment.

Our Process From Consultation to Completion

When you work with ASF Corporation, you can expect a seamless, professional experience:

- Initial Consultation: We discuss your project requirements, timeline, and budget constraints.

- Site Assessment: Our geotechnical team evaluates your site conditions to determine the optimal foundation solution.

- Custom Proposal: We develop a detailed proposal including pile specifications, timeline, and cost estimates.

- Project Planning: Once approved, we create a comprehensive project plan and mobilize resources.

- Construction: Our experienced team executes the pile installation following our proven methodology.

- Quality Assurance: We conduct rigorous testing to verify pile integrity and load-bearing capacity.

- Project Completion: We provide complete documentation and support for the next phase of your construction project.

Frequently Asked Questions

Here are the most common questions people have about cast in situ piles:

What are cast in situ pile?

Cast in situ pile are concrete piles that are constructed by excavating soil and pouring concrete directly into the hole at the construction site. A casing is built and strengthened with rebar, and concrete is poured as the casing is vibrated out of the ground to create a simple pile.

What are the main benefits of using cast in situ pile?

Cast in situ pile offer deep foundation support, are adaptable to various soil types, and allow for real-time monitoring of construction quality. They’re not subjected to handling or driving stresses, and they don’t cause vibrations that might affect surrounding structures.

What types of cast in situ pile are available?

The most common types include Simplex Piles (basic method using a hollow cylinder steel pipe), Franki Piles (using drop weight and temporary steel casing), Vibro Piles (utilizing vibrating casing), Bored Cast In Situ Piles, and Under-Reamed Piles with enlarged bases for additional bearing capacity.

How long do cast in situ pile last?

Under favorable conditions, cast-in-situ pile can last decades, often exceeding 100 years, with proper construction and materials.

What is the difference between precast and cast in situ pile service?

Cast-in-situ concrete is cast on-site, whereas precast concrete is manufactured in a factory and delivered to the location. Cast in situ pile service can be modified during installation to adapt to unexpected soil conditions.

What is the curing time for cast in situ concrete pile?

Cast-in-situ concrete pile have a relatively long curing time. When the temperature is above 5°C (40°F), curing should last at least 7 days or until 70% of the required strength is reached.

Can cast in situ pile be used in waterlogged site?

Yes, cast in situ pile service can be effectively used in waterlogged site with appropriate techniques, such as casing or slurry, to keep the hole open during construction.

What soil conditions are suitable for cast in situ pile?

Cast-in-situ pile are highly versatile and can be used in a wide range of soil types, from soft clays to hard rock. The specific design and construction method can be adapted to suit the soil conditions of a particular site. They are particularly suitable in soils with poor drainage qualities.

What are the limitations of cast in situ pile construction?

Some limitations include: pouring concrete from height can reduce quality due to segregation; additional piling should be avoided close by until the initial pile has set; reinforcement cages can be displaced if not properly secured; and they cannot be used in areas with strong groundwater flow or high artesian pressure.

What is the typical construction process for cast in situ pile?

The process typically involves: site layout and preparation; boring the pile hole using hydraulic rigs or manual augers; borehole operation and cleaning; fabricating and installing the reinforcement cage; cleaning the hole using tremie pipes and bentonite slurry; pouring concrete through a tremie pipe; and finally, pile head breaking for integration with the structure.

Ready to Build on a Solid Foundation?

Don’t compromise on the foundation of your construction project. Contact ASF Corporation today for expert cast in situ pile services that ensure the long-term stability and success of your building.

Visit Us: Vashantek, Dhaka Cantonment Dhaka-1206, Bangladesh.

Call Us: +88 01907-636827

Email Us: info@asfcorporation.com

Request a Consultation: Fill out our quick contact form below to schedule a site assessment and receive a customized quote for your project.

Download Brochure

BENEFITS

Rigorous attention to detail ensuring accurate earthwork execution.

Application of cutting-edge technology for cost-effective operations.

Comprehensive service covering all aspects of mass earthworks.

Efficient and timely completion of tasks to keep your project on schedule.

Frequently Asked Questions (FAQ’s)

What is piling and why is it used in construction?

Piling is a deep foundation technique used to transfer structural loads to deeper, more stable soil layers when the surface soil is weak or unstable.

What are the main differences between steel, wood, and concrete piles?

Steel piles are strong and durable, suitable for deep foundations; wood piles are cost-effective and used for lighter structures; concrete piles offer high load capacity and resistance to corrosion.

When should steel piling be used?

Steel piles are ideal for projects requiring high strength, deep penetration, or in corrosive environments where coated or treated piles are necessary.

Is wood piling still used in modern construction?

Yes, wood piling is still used, particularly for temporary structures, marine applications, and in areas where soil conditions are compatible and moisture helps preserve the wood.

What are the benefits of concrete piling?

Concrete piles are highly durable, resistant to corrosion and chemical attacks, and can bear heavy loads, making them suitable for large buildings and bridges.

How long do steel, wood, and concrete piles typically last?

With proper treatment and conditions:

- Steel: 50–100+ years (depending on corrosion protection)

- Wood: 30–50 years (in wet conditions)

- Concrete: 50–100+ years

Which type of piling is most cost-effective?

Wood piles are generally the most affordable for shallow foundations, while concrete and steel piles are more costly but offer higher strength and longevity for complex or heavy structures.

Can these different types of piles be used together in one project?

Yes, mixed piling systems are sometimes used when different parts of a structure have varied load or soil requirements.

What factors determine the choice of piling material?

Soil conditions, load requirements, environmental exposure, cost, and the design life of the structure all influence the choice of piling material.

Piling is a deep foundation technique used to transfer structural loads to deeper, more stable soil layers when the surface soil is weak or unstable.

Steel piles are strong and durable, suitable for deep foundations; wood piles are cost-effective and used for lighter structures; concrete piles offer high load capacity and resistance to corrosion.

Steel piles are ideal for projects requiring high strength, deep penetration, or in corrosive environments where coated or treated piles are necessary.

Yes, wood piling is still used, particularly for temporary structures, marine applications, and in areas where soil conditions are compatible and moisture helps preserve the wood.

Concrete piles are highly durable, resistant to corrosion and chemical attacks, and can bear heavy loads, making them suitable for large buildings and bridges.

With proper treatment and conditions:

- Steel: 50–100+ years (depending on corrosion protection)

- Wood: 30–50 years (in wet conditions)

- Concrete: 50–100+ years

Wood piles are generally the most affordable for shallow foundations, while concrete and steel piles are more costly but offer higher strength and longevity for complex or heavy structures.

Yes, mixed piling systems are sometimes used when different parts of a structure have varied load or soil requirements.

Soil conditions, load requirements, environmental exposure, cost, and the design life of the structure all influence the choice of piling material.